NX X Manufacturing Essentials

Visualize 3D part data and CAM setups and extend your manufacturing capabilities with add-ons for metrology, additive, production line planning & more. NX X Manufacturing Essentials is a scalable solution powered by the cloud that extends access to manufacturing data across the enterprise.

When NC programming capabilities aren’t required, NX X Manufacturing Essentials serves as an ideal entry point — enabling users to visualize and interact with 3D part models and manufacturing information directly within the NX X Manufacturing environment.

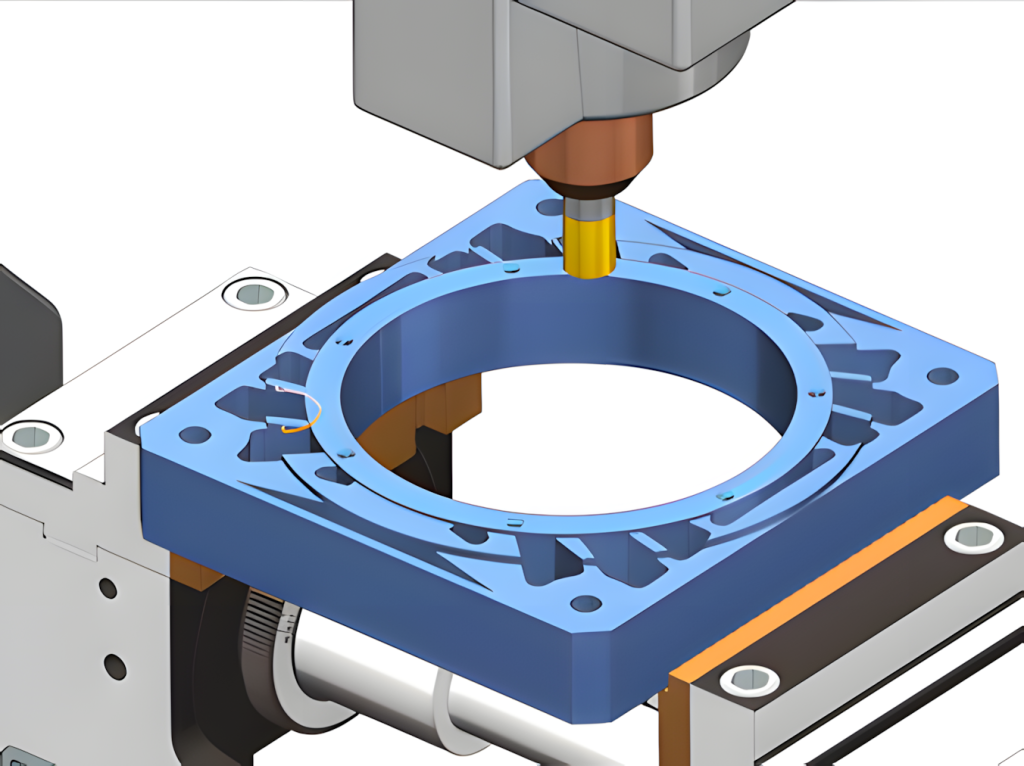

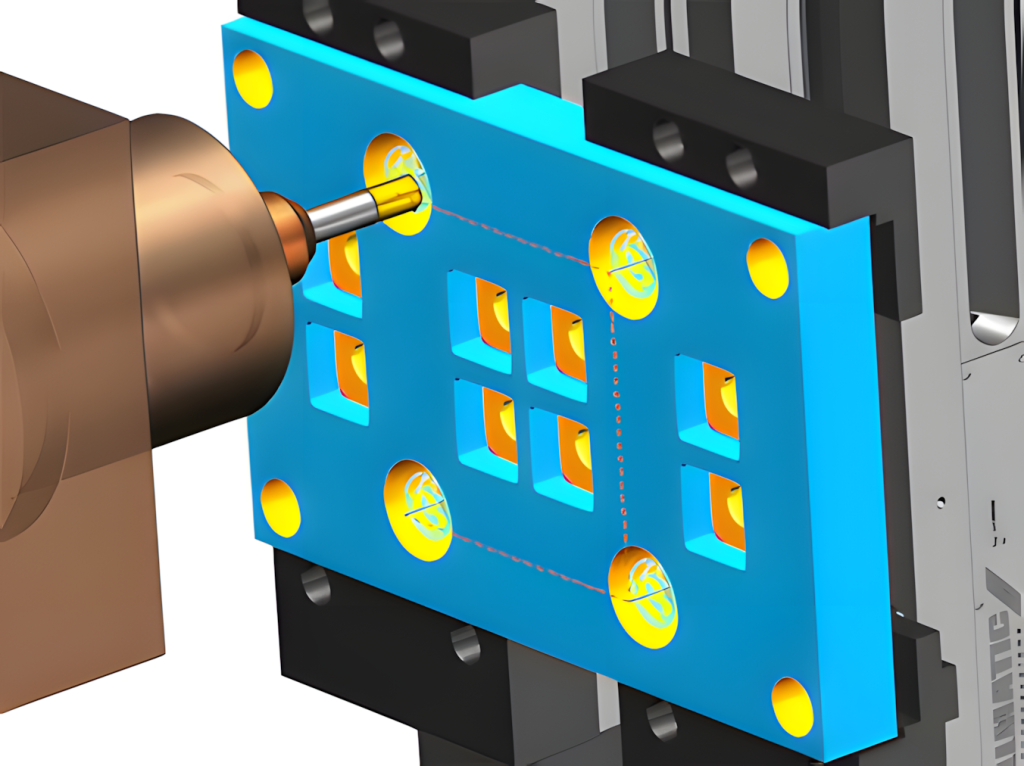

NX X Manufacturing Standard

Automate prismatic part programming using 2.5-axis milling, hole making, turning and on-machine probing capabilities powered by cloud technologies.

NX X Manufacturing Standard incorporates automated prismatic part programming using computer-aided design (CAD) and computer-aided manufacturing (CAM), featuring 2.5-axis milling, hole making, turning and on-machine probing capabilities. With seamless integration to top-tier CAD tools, it streamlines prismatic part programming, reducing programming time by up to 90%.

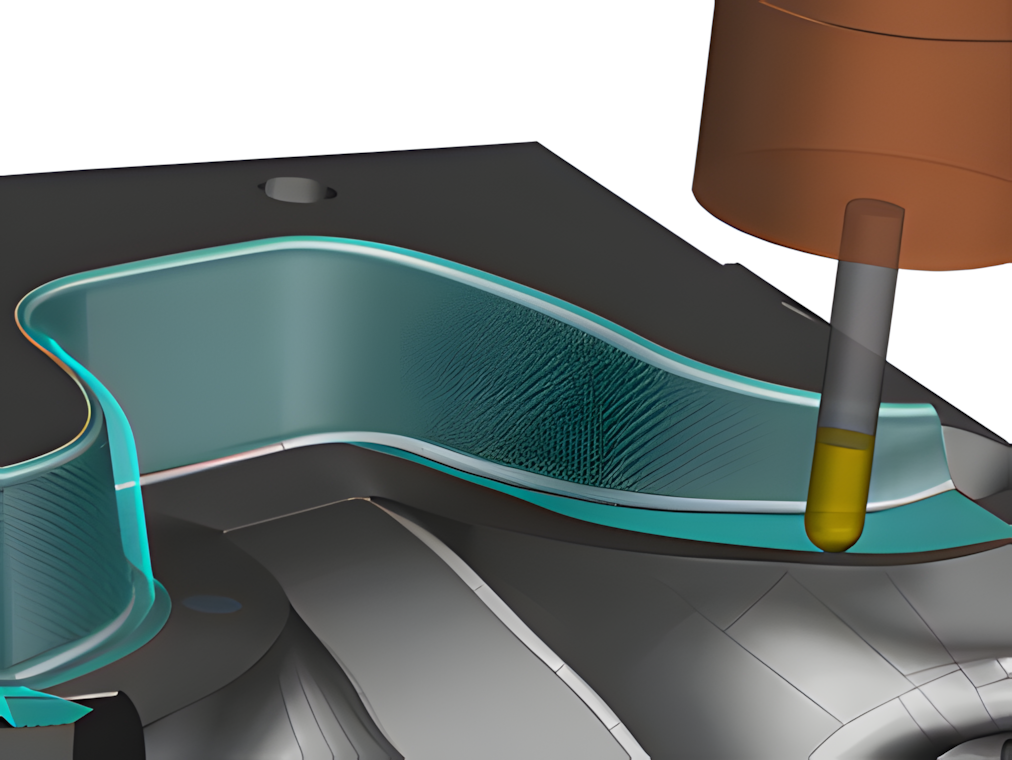

NX X Manufacturing Advanced

Program freeform parts with NX X Manufacturing Advanced, which builds upon the Standard product, using 3-axis milling capabilities powered by cloud technologies.

NX X Manufacturing Advanced builds upon the Standard product, incorporating advanced 3- and 2.5-axis milling, turning and on-machine probing capabilities, among other functionalities. The industry-leading integrated CAD/CAM tools streamline the preparation and programming of the most demanding freeform parts, such as molds and dies. The powerful toolpath technologies enable the machining of parts with superior surface finish while reducing cutting time by up to 60%.

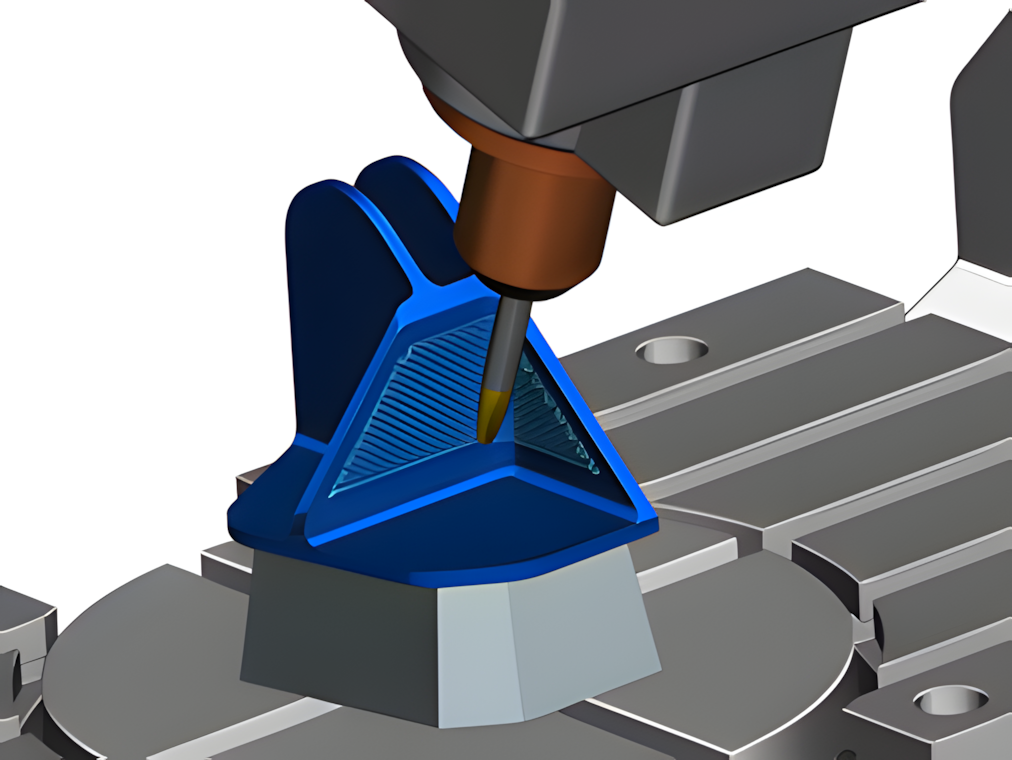

NX X Manufacturing Premium

Simplify programming of complex parts with NX X Manufacturing Premium, building upon the Advanced product, with multi-axis machining powered by cloud technologies

NX X Manufacturing Premium is the most comprehensive package building upon the Advanced product. It incorporates simultaneous 5-axis milling and rotary machining, along with 3—and 2.5-axis milling, turning and on-machine probing capabilities.

NX X MANUFACTURING KEY BENEFITS

Which NX X Manufacturing solution is right for you?

| Feature List |

NX X Manufacturing Standard Automate prismatic part programming using CAD/CAM and tools powered by cloud technologies. |

NX X Manufacturing Advanced Program freeform parts with advanced CAD/CAM and collaboration tools powered by cloud technologies. |

NX X Manufacturing Premium Machine complex parts with extensive CAD/CAM & collaboration tools powered by cloud technologies. |

|---|---|---|---|

| Cloud collaboration | ✓ | ✓ | ✓ |

| 2.5 axis milling | ✓ | ✓ | ✓ |

| Feature-based machining | ✓ | ✓ | ✓ |

| Turning | ✓ | ✓ | ✓ |

| 3 axis milling | ✓ | ✓ | |

| 3+2 positioning machining | ✓ | ✓ | ✓ |

| Rotary machining operations | ✓ | ||

| 5 axis milling | ✓ | ||

| On-machine probing | ✓ | ✓ | ✓ |

| Machine tool simulation | ✓ | ||

| Teamcenter integration for NX | ✓ | ✓ | ✓ |

| Hole-making technology | ✓ | ✓ | ✓ |

| Machine setup modeling | ✓ | ||

| Synchronous modeling | ✓ | ✓ | ✓ |

| Feature-based solid modeling | ✓ | ✓ | ✓ |

| Basic freeform modeling | ✓ | ✓ | ✓ |

| Advanced freeform modeling | ✓ | ✓ | |

| Core convergent modeling | ✓ | ✓ | ✓ |

| CAD translators | ✓ | ✓ | ✓ |