Take Production Management to a New Level With Opcenter APS

Key Features and Capabilities

Opcenter Planning PL helps manufacturers create optimized production schedules by considering

- Machine capacities

- Material availability

- Labor resources to minimize lead times

- Improve resource use

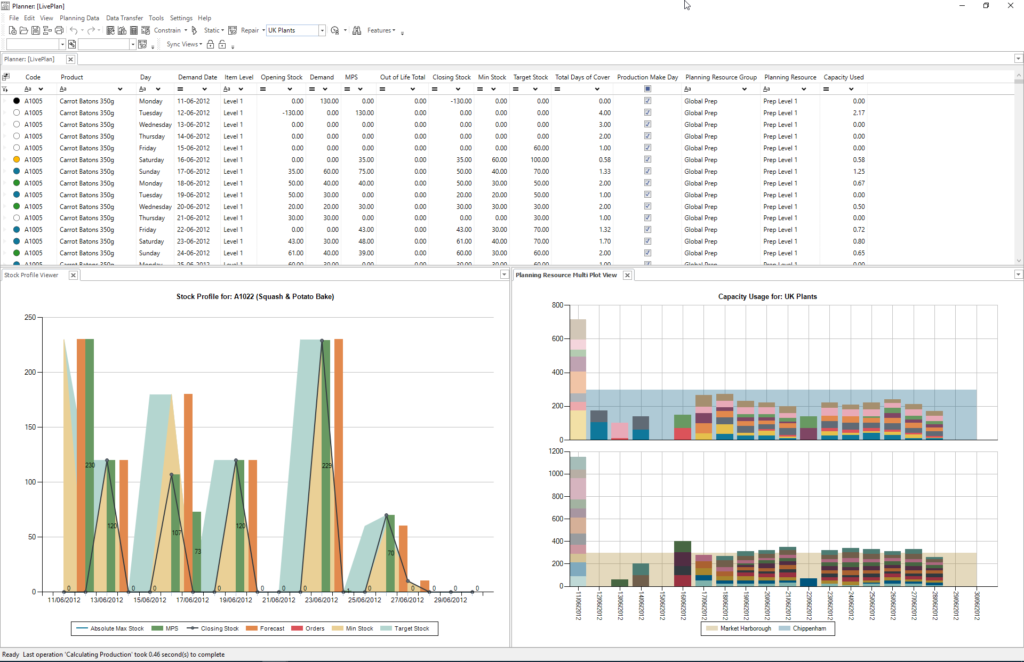

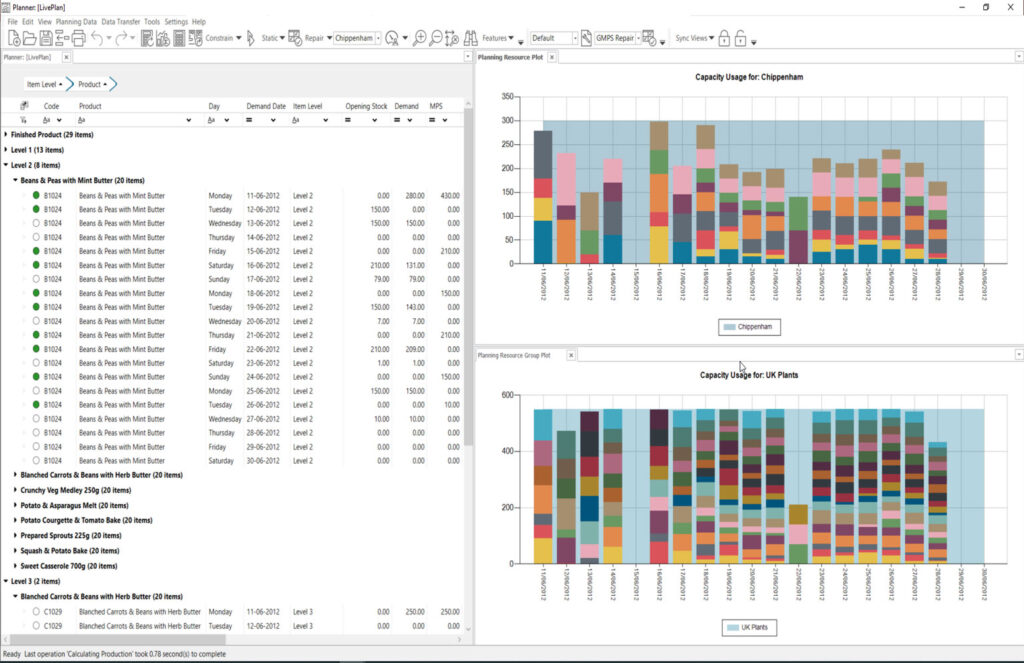

Opcenter Planning PL integrates with ERP and MES systems to provide real-time data on orders, inventory, and production, ensuring accurate and current planning decisions

- It offers Gantt charts, resource histograms, and capacity views for visualizing and analyzing production schedules

- Simulation capabilities enable “what-if” analysis to evaluate and optimize scheduling decisions.

- Opcenter Planning PL manages complex constraints like setup times, changeovers, and production priorities

- Plannerscan set rules and preferences to align scheduling with production goals and customer requirements.

- The software provides reports on KPIs for production efficiency, schedule adherence, and resource use

- Analytics tools offer insights into performance and highlight improvement opportunities

In summary, Opcenter Planning is a robust solution that empowers manufacturers to achieve operational excellence through effective planning, scheduling, and execution of production processes. Its capabilities support agile and efficient manufacturing operations in today’s competitive global market.

Benefits

Optimizes production schedules and resource utilization, reducing downtime and improving overall efficiency

Provides real-time insights into productiona activities, enabling proactive decision-making and response to changes

Minimizes inventory costs, reduces overtime expenses, and optimizes use of production resources

Ensures on-time delivery of orders and improves customer satisfaction by meeting delivery commitments

Why Opcenter PL is the Right Choice?

Utilize sales data and orders to estimate future market demand accurately.

Assess whether resources such as raw materials, workforce, and machinery are sufficient to meet the plan

Avoid overproduction or stockouts by optimizing your production schedule.

Quickly adjust your plans to respond to rapid market changes