Managing MaterialShortages with Opcenter Scheduling

Key Features and Capabilities

Optimized production schedules and maximize efficiency and minimize downtime by considering

- Machine Capacities Material Availability

- Labor Constraints

- Setup Times

- Order Priorities

Integration with Enterprise Systems

- ERP and MES systems

- Ensuring synchronized production schedules with business objectives

- Enabling real-time data exchange for better decision-making

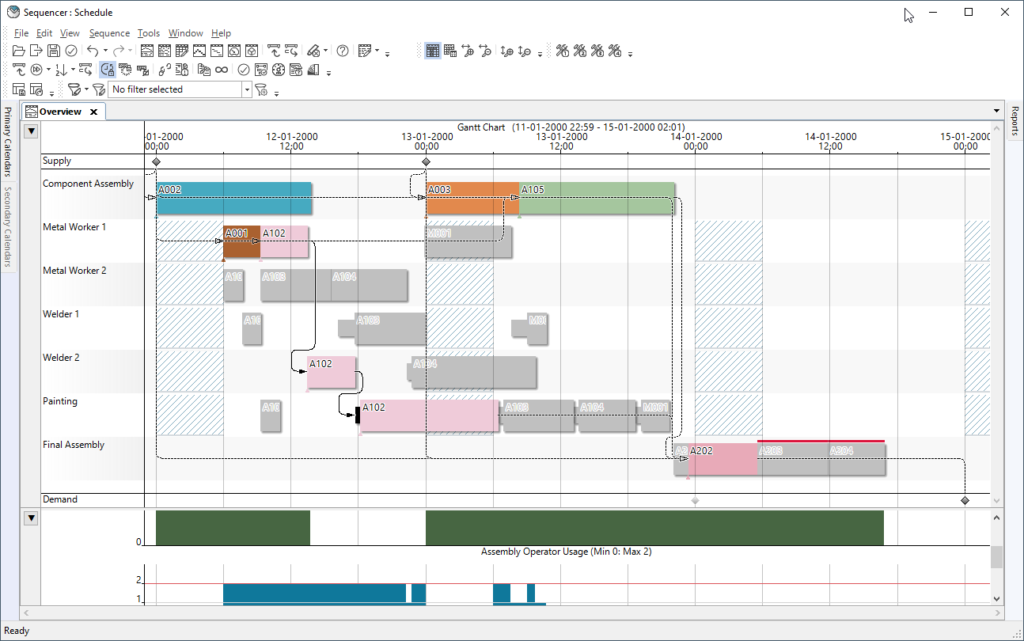

Opcenter Scheduling offers intuitive visualization tools like

- Gantt charts, allowing planners to view, analyze, and adjust production schedules to optimize resource use and production flow

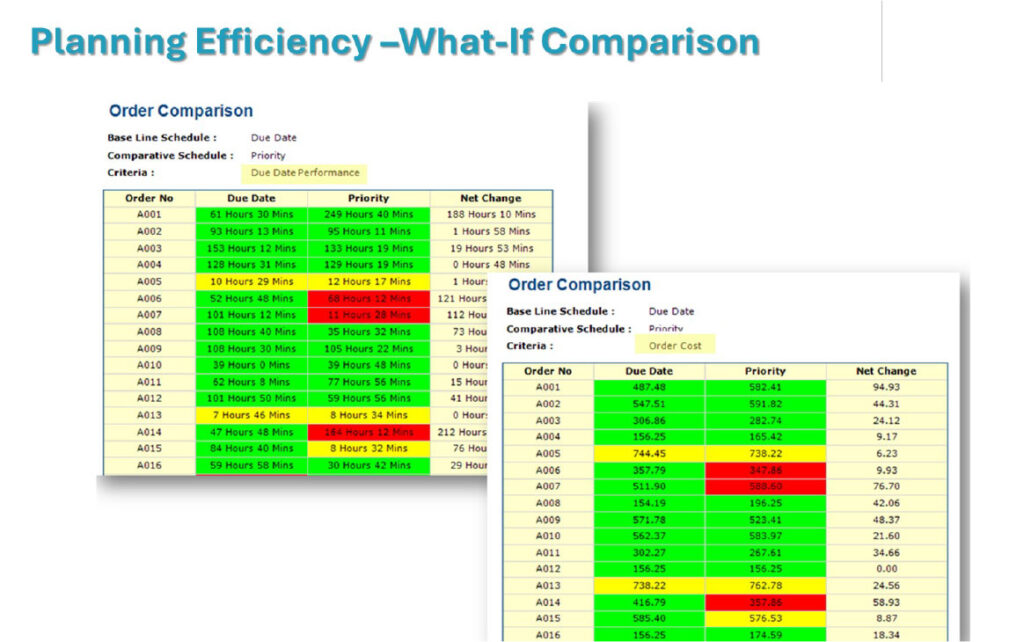

Users can perform scenario analysis and what-if simulations

- Helping planners evaluate different scenarios

- Identify potential issues

- Explore alternative scheduling options for informed decision-making

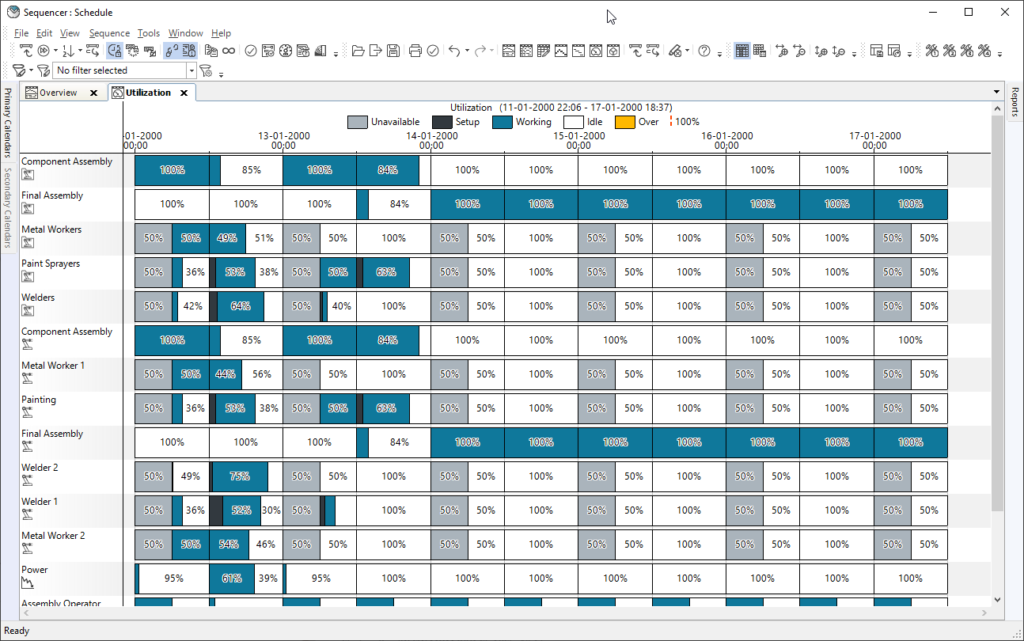

The software optimizes

- esource allocation and utilization

- Balancing workloads and minimizing idle time to maximize productivity and throughput while maintaining quality

Opcenter Scheduling is flexible and customizable

- Supporting configurable rules, workflows, and user-defined parameters to meet the needs of various manufacturing industries and production environments

For regulated industries like aerospace and pharmaceuticals, Opcenter Scheduling offers features for tracking and documenting schedules to ensure compliance and facilitate audits

The software provides

- Real-time monitoring to track production progress

- Ensure schedule adherence

- Alert users to deviations

- Helping maintain efficiency

- Quickly address disruptions

Benefits

Optimizes production schedules to reduce lead times, minimize idle time, and enhance resource utilization.

Provides actionable insights through visual analytics and scenario analysis, facilitating informed decision-making,

Reduces inventory costs, minimizes overtime expenses, and optimizes energy consumption.

Ensures on-time delivery and reliability, meeting customer expectations and maintaining competitiveness.

Why Opcenter SC is the Right Choice?

Optimize production plans with real-time adjustments based on machine, material, and labor constraints.

Reduce downtime and maximize resource utilization for better ROI.

Get a full view of your production flow and make faster, data-driven decisions.

Our specialists work closely with you to ensure successful setup, customization, and long-term results.

Description

Industry Applications:

Opcenter Scheduling is widely used across various industries including

- Automotive

- Aerospace

- Electronics

- Pharmaceuticals

- Consumer goods

- Discrete manufacturing sectors

It caters to both make-to-order and make-to-stock production environments, supporting complex scheduling requirements and helping manufacturers meet customer demands effectively.

In summary, Opcenter Scheduling empowers manufacturing companies to achieve operational excellence by

- Optimizing scheduling processes

- Improving productivity

- Aligning production activities with strategic business goals