Turn decisions from “Feeling” to “Real data” with production simulation software.

In today’s manufacturing management, speed and accuracy are critical. Many factories and production managers face the challenge of improving their production lines without enough supporting data. Decisions to change machines or processes may cause unnecessary downtime, wasting both time and business opportunities.

Our service: Siemens Tecnomatix Plant Simulation is the answer. With Digital Twin technology, it functions as a production system simulation software that lets you accurately simulate your production line before making any changes on the shop floor.

Why Plant Simulation?

Plant Simulation is a production simulation tool that gives you a structured, end-to-end view of operations—from upstream to downstream. Whether it’s job sequencing, machine utilization, material handling, or even worker behavior, the system can identify potential bottlenecks, analyze energy usage, and evaluate OEE in real time.

Pain points for Production managers

- Waste time to build simulation models yourself—real usage comes too late.

- Lack of programming/SimTalk expertise and isn’t comfortable modeling complex flows.

- Need support data to make decisions: Bottleneck, Cost, Energy, Layout.

Key features that fit production managers

- Bottleneck Analyzer: instantly spots bottlenecks (example case: increased output up to 10.5%).

- Cost Analyzer & Energy Analyzer: analyze costs and usage patterns to reduce expenses in a structured way (example case: >20% reduction).

- Sankey Diagram: visualize internal movement paths and cut transport distance by up to 30%.

- Genetic Algorithm & Layout Optimizer: test alternative machine/aisle/storage positions to find the best solution (example case: 70% reduction in transport rate).

- Experiment Manager + What-if: test multiple scenarios quickly.

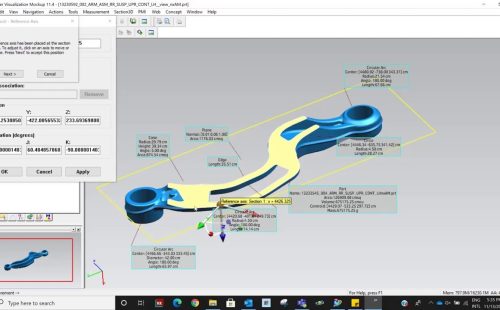

- Gantt & 3D VR Presentation: communicate results to executives with realistic visuals.

Make better decisions with real data.

The system connects to ERP or MES to build an accurate Digital Twin, allowing you to run safe “what-if” experiments. For example, if you add two more AGVs, how will throughput change? If you increase the buffer, how much more output will you get?

From cycle-time confirmation to strategic decisions

Plant Simulation supports everything from basic use (confirming lead time and screening bottlenecks) to advanced use (live data connections, sustainability analysis, and real-time cost control).

Summary

If you want to strategically elevate your production line, reduce the risk of trial and error in the real factory, and make informed decisions based on real data, Plant Simulation is a production simulation software you shouldn’t