Plant Simulation: From Deep Insight to Enterprise-Level Advantage

For organizations that already have robust digital systems—ERP/MES/APS, BI, and IIoT—the challenge is no longer “Do we have data?” but “How quickly can we decide with confidence, and how widely can we scale those decisions?” Changing lines structures or capacity in production lines carries a high opportunity cost and risk of downtime. Our service: Siemens Tecnomatix Plant Simulation serves as a Digital Twin of your production lines, enabling executives to “see the future” before committing, investing, and rolling out across a network of plants.

Pain Points for Professional-Level Organizations

- Complex system landscapes across multiple plants/countries require shared standards and model governance.

- Simultaneous pressure on Throughput, OEE, Lead Time, Cost/Unit, and Sustainability (energy/CO₂).

- What-if/Scenario planning in Excel or slide software is insufficient; leaders require quantified simulations linked to real data.

- Need to scale & reuse a model from one plant as a blueprint for swift deployment elsewhere.

Why Plant Simulation (for large Eenterprises)

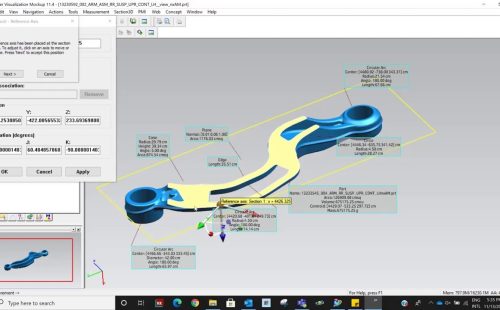

- Digital Twin: Build/manage object-oriented models with ready-to-use libraries/templates, plus 2D and 3D visualization for realistic communication.

- End-to-End Live Data: Ingest data from ERP/MES/APS/IIoT via ODBC/OPC UA/MQTT/Data Lake to DataFit the model so it reflects actual production.

- 3. Scenario & Optimization at Scale: Run DOE/Experiment Manager and apply Genetic Algorithm/Neural Network/Fuzzy Logic to find best-value settings automatically.

- Graphical outputs for analysis: Convert simulation results into business KPIs (Throughput/OEE/Energy/CapEx/OpEx/CO₂) and publish to three-level dashboards (shop-floor, managers, executives).

What You Gain When Plant Simulation Becomes Your Decision Core

- Bottleneck Intelligence: Identify bottlenecks before they occur (example cases show ~+10.5% output).

- Energy & Sustainability Analytics: Model energy to reduce power use and carbon (>20% depending on context and data).

- Flow & Layout Excellence: Use Sankey/heatmaps to redesign logistics and storage (examples show ~30% shorter travel) and Layout Optimizer (examples show ~70% less internal transport).

- Risk-Free What-if: Add shifts/buffers, resequence work, add AGVs—without touching the production lines—and see impacts on Throughput, WIP, Lead Time, and Cost/Unit per scenario.5.

Note: Figures are examples from real implementations; outcomes depend on data quality and project scope.

Governance-Driven Enterprise Approach

- Executive Discovery & KPI Alignment — Define business hypotheses and KPIs (e.g., Throughput, Cost/Unit, kWh/Unit, CO₂/Unit).

- Reference Model & DataFit — Build a standard model and connect data pipelines from ERP/MES/IIoT to validate accuracy.

- Scenario Portfolio & Optimization — Create CapEx and quick-win what-if portfolios; run optimization to find measurable best configurations.

- CoE & Roll-out — Establish a Center of Excellence to govern model standards/versions/access and scale to other plants/countries in a controlled way.

Expected Business Impact

- Shorter decision cycles—from weeks to days/hours—enabled by data-linked simulations.

- Reduced CapEx mis-investment by seeing outcomes and sensitivities before spending.

- Greater sustainability by tying energy/carbon KPIs directly to capacity decisions.

- Blueprint & Scale: Create a reusable blueprint model for network-wide roll-outs and continuous improvement (CI).

Summary

For enterprises that must predict, adapt, and scale simultaneously, Plant Simulation becomes a decision toolengine that turns data into a strategic advantage—reducing downtime risk, investment uncertainty, and time-to-impact at an enterprise scale.

Executive Demo & Strategy Session

Book a 45-minute executive demo to review real use cases, enterprise data integration, and a roll-out roadmap.