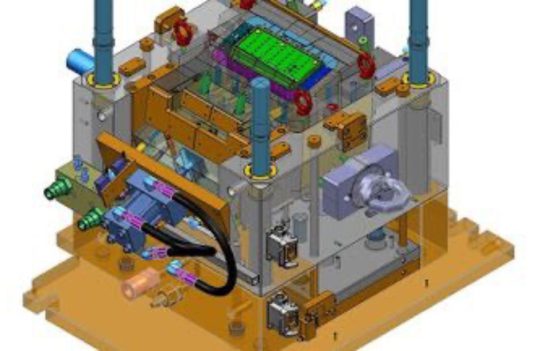

In the design and production process Mold design is a difficult process to improve performance because it depends on the shape of the product. Each product is unique and has many parts.

Additionally, although the benefits of converting mold designs previously done in 2D into 3D solids have been recognised,

The issue of increased labor hours due to 3D design is evident in the design of molded structural parts.

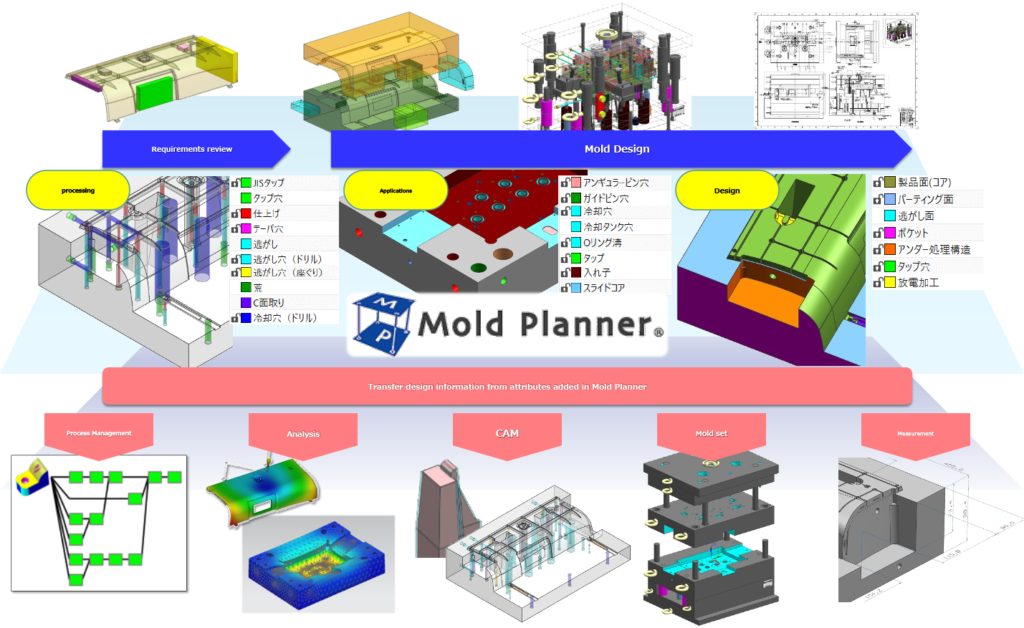

“Mold Planner” is a mold design support application developed to solve these problems.

Mold Planner Functions

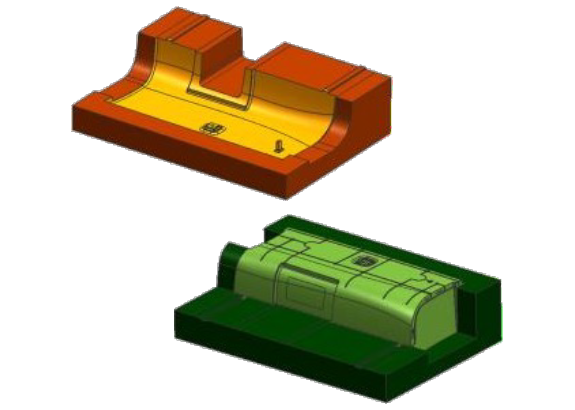

Mold splitting and nesting creation functions

- Automatic parting surface creation function

- Continuous hole filling surface function

- Automatic cavity core division function

- Various commands required for nest division

- Core pin creation function

- Flange attachment function for nests

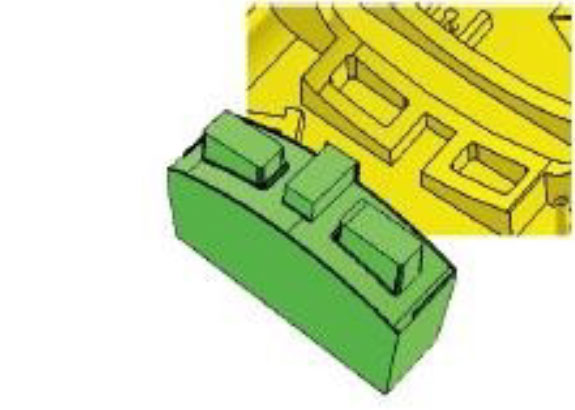

Electrode creation function

- Electrode creation position detection function by recognizing the cutting range based on tool diameter, tool length, etc.

- Electrode shape creation function compatible with oscillation types (angle, circle, sphere)

- Escape and holder creation support function

- Mold and die industry association recommended “EPX format“

- Version 2 output function

Standard Parts Library

- Provides a library of catalog parts from seven mold and part manufacturers, including Misumi Corporation.

- Provides a mold base library from Futaba Corporation.

- Provides an Dentsu Soken template library.

- Library registration function for in-house standard parts.

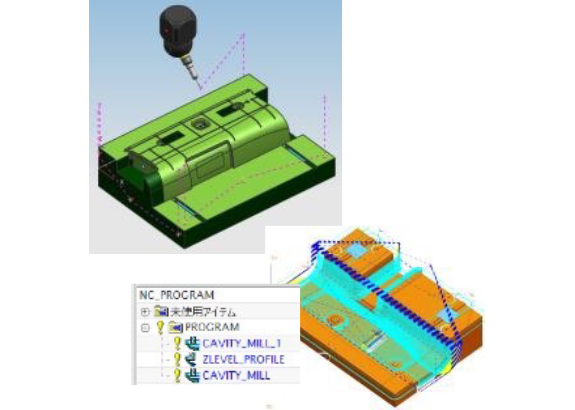

Data linkage to downstream processes

- Automatic creation of drilling data

- Data linkage to NX/CAM

- Data linkage to inspection department

- Data reuse in analysis tools

Data Validation Function

- Detection of undercuts, cavities, and core shapes using product model shape recognition function

- Abundant 3D model verification functions for taper angle, face curvature, etc.

- Product wall thickness confirmation function

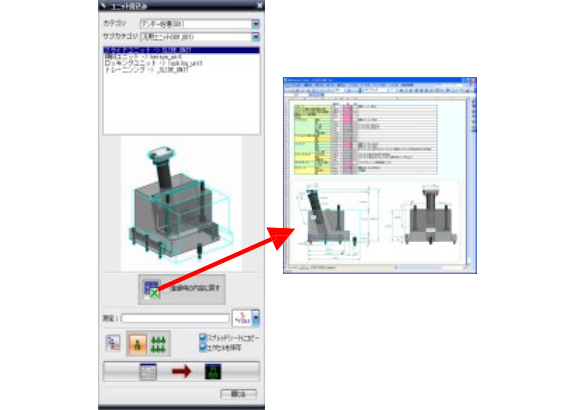

Detailed Design Function

- Automatic ejector pin hole/cooling hole depth design function

- Construction of mold units incorporating design intent

- User registration function for easy construction and editing through collaboration with Excel

- Interference check function for parts and holes

- Function for creating parts lists, purchase orders, etc.

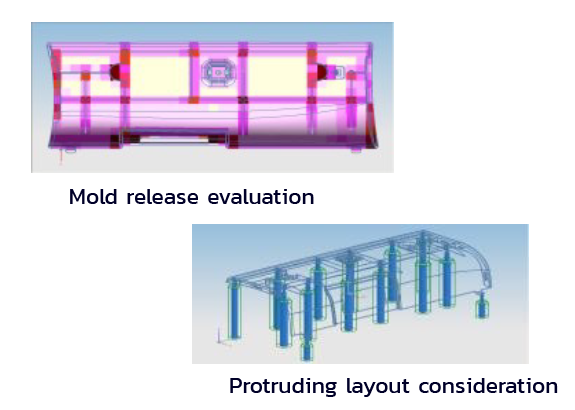

Mold concept design function

- Extrusion concept layout design while checking mold release properties

- Cooling concept design with a single stroke

- Concept layout with a 2D feel

- Parting line design function using the navigator

- Runner design function

- Function to support designers in trial and error

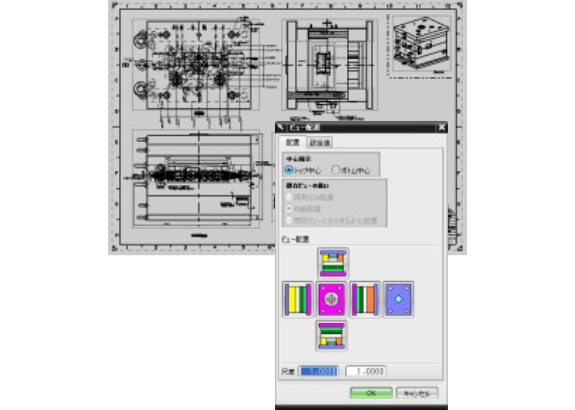

Mold drawing function

- Title block creation function from part attributes

- Create movable side assembly drawings and fixed side assembly drawings with one button

- Drawing template loading, etc.Reduces the labor required for drawing

- Automatic hole coordinate list creation function

- Fit tolerance drawing function

- Automatic symbol placement function