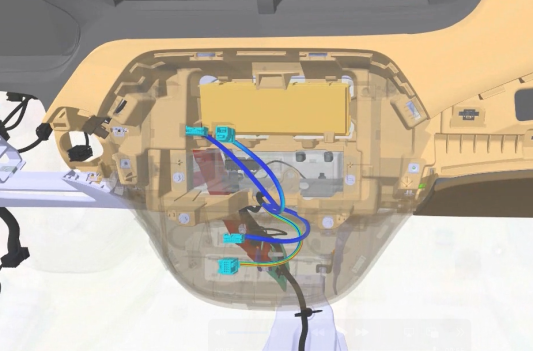

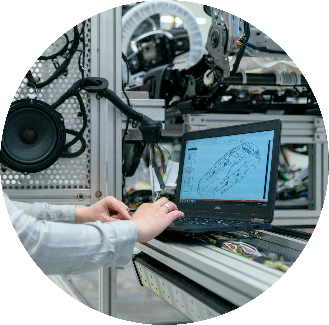

Transition from an iterative hardware-based process to a simulation-driven approach.

Improve and ensure quality by applying the software in design, virtual assembly, DMU processes, and troubleshooting, leading to higher product quality and enhanced durability of flexible parts.

Foster interdisciplinary collaboration with IPS Cable Simulation, a fast-decision-making platform that connects different divisions across all stages of the product process, helping to detect flaws and ensure product quality.”

Benefits

Repeat realistic positions and movements considering weight, rigidity and clip flexibility

Simulate interference and contact itself, other cables and surrounding components

Superior real-time performance, with real-time behavior tracking movement

INDUSTRY CHALLENGES

Low failure rates

High safety requirement

Increasing complexity

Realistic behavior

Shorten time to market

KEY CAPABILITIES

Routing: automatically distribute cables in consideration of contact with surrounding parts

Cable connection: create clip and connectors with degrees of freedom

Motion: defining cable motion behavior that follow the motion of moving part

Analysis: function that measures the force applied and the distance to the surrounding components

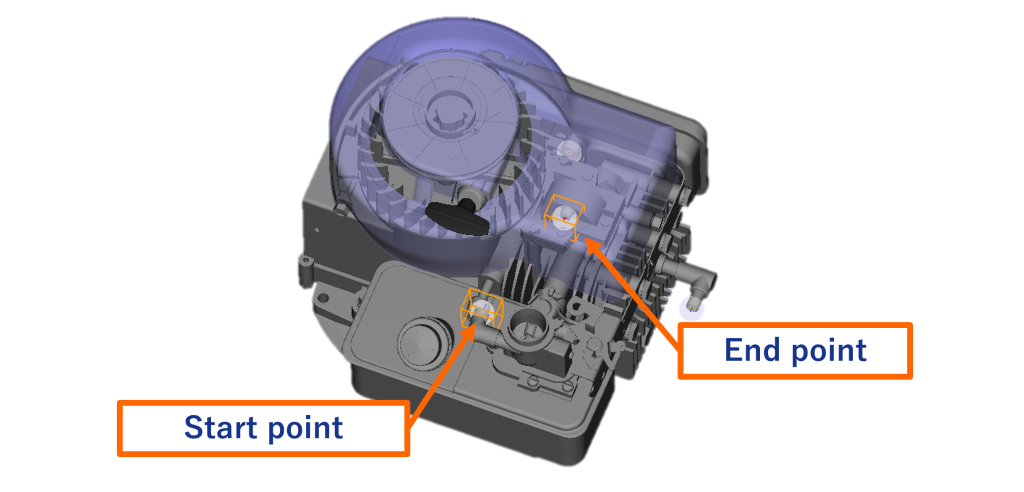

How to face the challenges on the hydraulic hoses of an excavator?

Hydraulic hose failures can result from twisting, abrasion, and bending due to moving parts like the boom or arm of an excavator. Proper fitting orientation is crucial to avoid friction and collisions with surrounding parts.

3D CAD modeling of hoses is challenging as they are treated as rigid entities, failing to capture their complex flexible behavior. This can lead to real-world issues.

A system that considersthe actual shape and moving parts is needed. IPS Cable Simulation addresses this by modeling realistic behaviors in real-time, reducing modeling time and meeting all requirements in an easy-to-use environment.

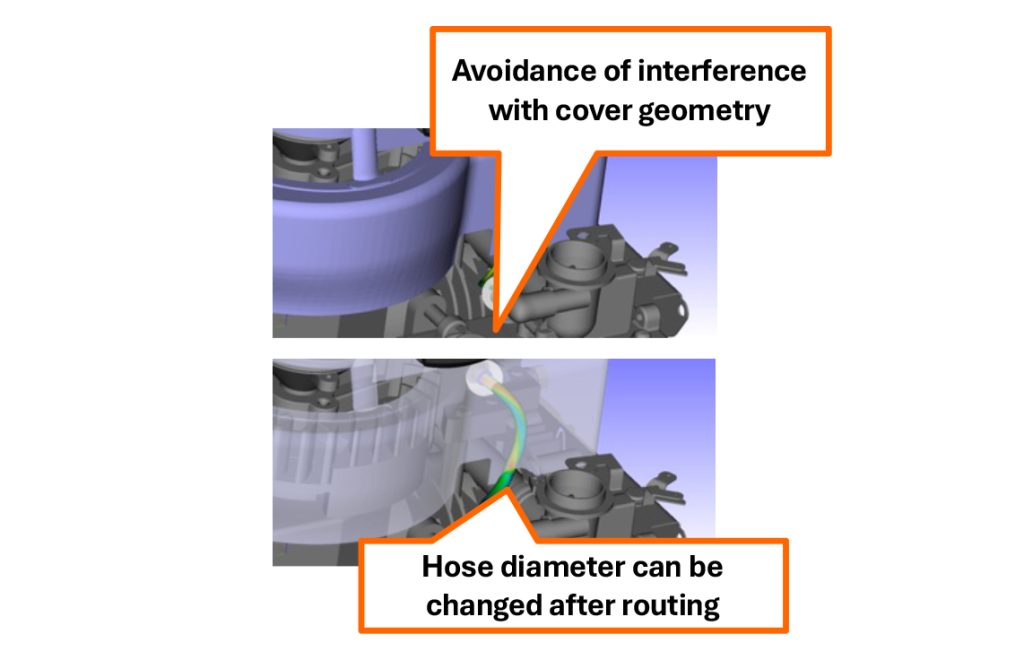

Home Appliance application case

In modern home appliances, various flexible components must be designed with precision to ensure efficient space utilization, durability under repeated use, and safety by preventing wear, leaks, or electrical issues. It also simplifies assembly and maintenance, optimizes performance for seamless power and fluid flow, and enhances the appliance’s reliability and overall user experience.

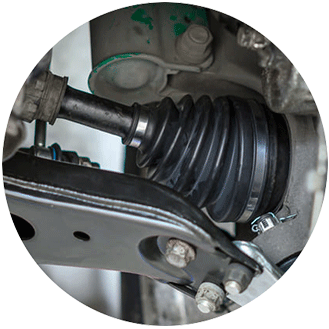

Motorcycle application case

Studying flexible hoses and cable harnesses in motorcycles is essential to ensure efficient routing within limited space, durability against vibration and motion, and safety by preventing wear, leaks, or electrical issues. It also simplifies assembly and maintenance, optimizes performance by ensuring seamless signal and fluid flow, and enhances the overall aesthetic appeal, contributing to reliability and a better user experience.

Railway application case

Are you interested in the challenges of cables and hoses at a railway front coupling? Find out how to correctly do a 3D mechanical design of these flexible parts.

At the front coupling of a railway there are various flexible parts that need to be considered and designed realistically, such as cables for power and signal transmission, grounding cables or compressed air hoses for air transmission between trains to ensure the function of the coupler.These increased requirements lead to the need for a virtual validation method without hardware testing and empirical values. With IPS Cable Simulation there is a software solution to meet the following tasks in a fully digital way at the early stages of the product development process.

3D mechanical design of hoses and cables in real-time

Correct length and design right from the start

Flexible components under the influence of motions

Fullfillment of assembly requirements

Consideration of cable stiffness

First virtual realistic behavior of cables and hoses