From the comfortable air circulation you enjoy in buildings to the clean water that you drink or shower with, these are all thanks to the work of an engineer. Engineers are responsible for designing, building, and maintaining a vast range of systems, technologies and structures that make living in the modern world possible. However, the demands of rapid progress in technology can become overwhelming for engineers. Society is used to wanting things fast, affordable, and accurate. The traditional trial-and-error approach that has become the norm in engineering has seen its limitations. This is where the revolutionary technology of Computational Fluid Dynamics (CFD) comes into play.

What is Computational Fluid Dynamics?

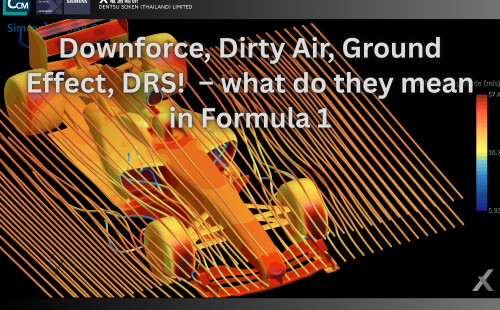

Computational Fluid Dynamics uses computer-based math to analyze and model how fluids, like air or water, will flow through different structures and environments. So instead of using real wind or water, the computer does the math to figure out how the fluid will move, swirl, and push against things. These simulations can show velocity, pressure, temperature, turbulence, and how fluids affect objects. It enables engineers to study complex phenomena such as turbulence, heat transfer, and aerodynamics. This is necessary to discover whether the technology or structure that will be built is worth pursuing. By modeling this online, engineers can improve and optimize designs without needing to spend time or money on physical experiments.

Introducing the Simcenter STAR-CCM+ CFD Software

At Dentsu Soken Thailand, we understand the importance that digital solutions have in the modern world. This is where Simcenter STAR-CCM+ CFD Software helps lessen the challenge between design and execution for many engineers. Simcenter STAR-CCM+ is a multiphysics computational fluid dynamics simulation software that can accurately model the physics that affect how complex products perform.

This powerful solution delivers significant advantages including:

- Real-world simulation that predicts a product’s performance success earlier in the design cycle

- Decreased time-to-market and fewer expensive failures

- A wide range of physics in a seamless, integrated user interface, improving realism and accuracy

With its visualization tools, scenario modeling, and real-time analysis, this technology works in tandem with advanced fluid dynamics modeling to minimize approximation and assumptions. It can help engineers see what is happening in designs, understand problems (such as where airflow is weak or where air is too hot or cold), and communicate design decisions clearly. Overall, it provides a comprehensive, accurate, and efficient range of capabilities that enable engineers to simulate even the most complex multiphysics applications from a single integrated platform.

There are many benefits to using CFD. This technology enables engineers to study complex interactions that are difficult or impossible to measure in real-world conditions, leading to smarter design decisions.

- It helps engineers gain deeper insights, visualizing fluid flow and thermal patterns that are hard to measure experimentally.

- It allows for virtual exploration of complex problems before investing in physical prototypes.

- It significantly reduces testing time and expenses by eliminating the need for numerous physical experiments and prototypes.

- It improves system efficiency and enhances overall performance with greater ease.

- It increases comfort and safety for end users through optimized design iterations.

- It shortens design cycles, which allows businesses to bring products to the market faster.

Simcenter STAR-CCM+ in Action: An HVAC System Case Study

A company called ABT used computational fluid dynamics to optimize buildings with high occupancy terminals in order to achieve better thermal comfort. The program modeled the airflow patterns and temperature distribution of an HVAC and cooling system design until it achieved an ideal result. It was even capable of coming up with a design for low flow-induced noise. Through these simulations, physical testing was greatly reduced while improving ventilation efficiency and achieving higher air quality and a comfortable temperature for the occupancy zones.

Using Simcenter STAR-CCM+ saved the company time, money, and energy – just as it promised. It also ensured that comfort metrics were achieved quickly and reliably within the project’s return-on-investment (ROI) timeline. This is just one of the many examples of how effective CFD can be. Its applications can go far beyond HVAC systems too, and can virtually benefit any industry where fluid dynamics is involved.

Let Dentsu Soken Thailand Become Your Trusted Partner in Digital Engineering Solutions

Now that you understand what computational fluid dynamics is and how it can be used to optimize designs or systems, it’s clear how powerful and effective it would be when it comes to operations where time, money, and energy are concerned. Whether it’s HVAC design for heating, cooling, and air circulation or fan and ventilation in gaming consoles or electronics, CFD gives engineers a more efficient way to test, refine, and come to ideal solutions virtually before building a physical model.

For companies looking to innovate their workflow and operations with advanced digital solutions, reach out to us at Dentsu Soken Thailand. We empower Thailand’s manufacturers with world-class Japanese expertise. With nearly 50 years of professional experience in consulting and information technology, we can provide Japanese-quality digital transformation with end-to-end solutions. Our innovative tools and actionable guidance can assist you in utilizing the full potential of CFD and modern simulation technologies.

For more information on our IT solutions or to schedule an appointment about Simcenter STAR-CCM+, please contact us at +66 (2) 632-9112 or send an email to Sales_TH@th.dentsusoken.com.