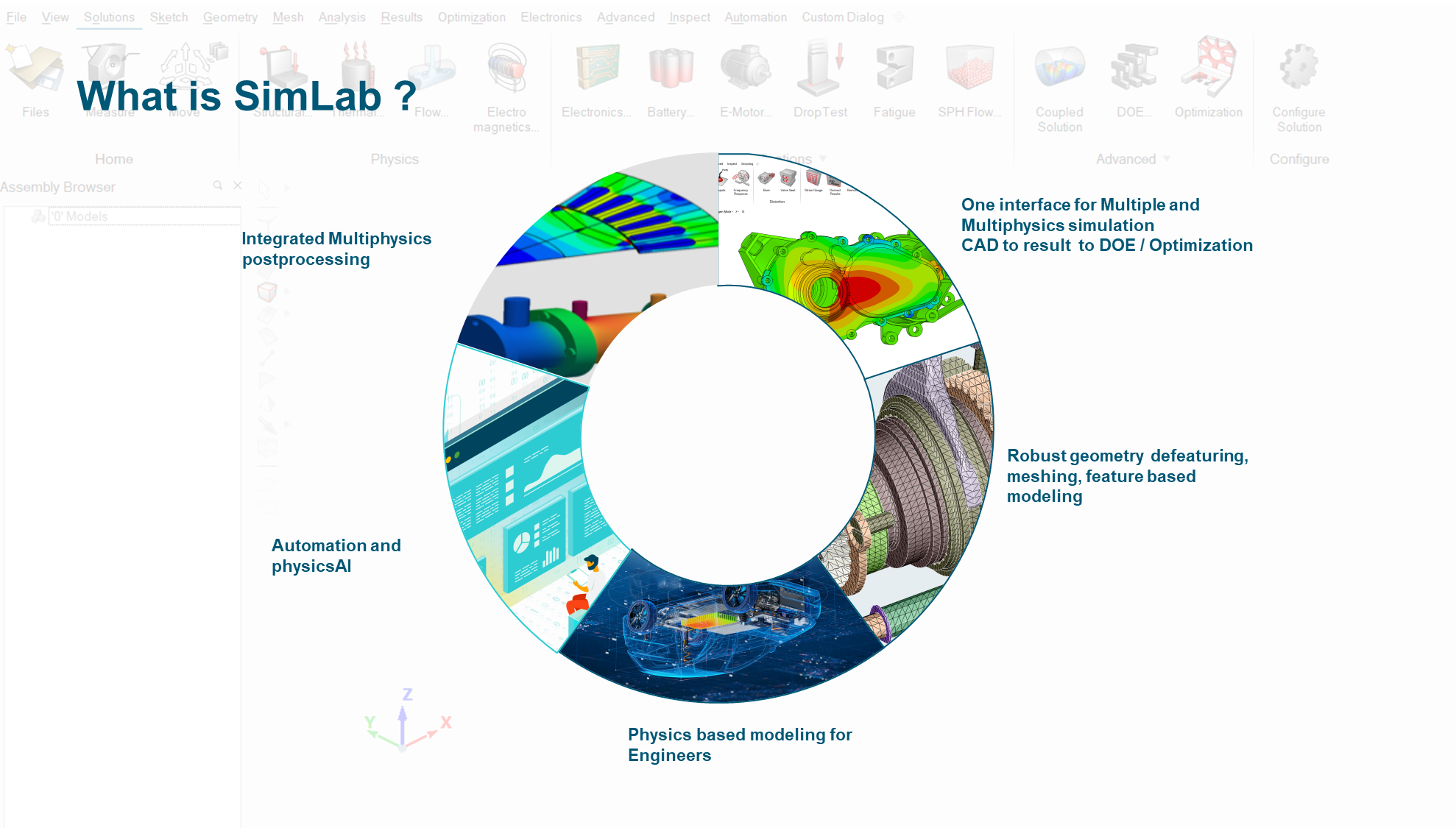

Key highlights

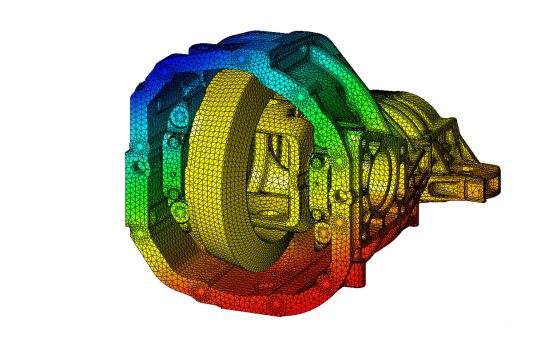

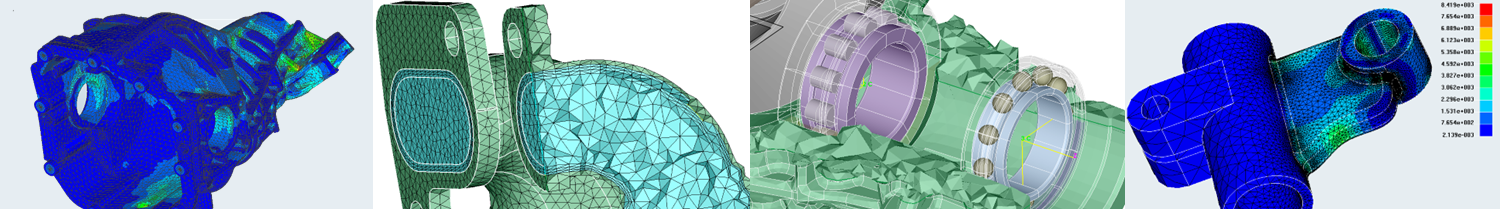

Advanced Meshing

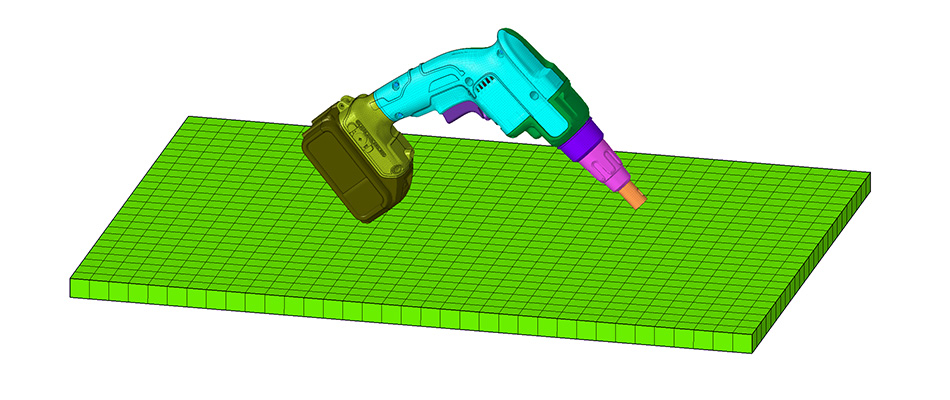

Generates high-quality meshes for a wide range of analyses: NVH, durability, fatigue, CFD, and more.

Automated mesh generation for efficiency and consistency.

Supports multiple element types: Tetra, Hexa, Quad, Tri, and 1D elements.

Feature-based meshing for improved accuracy on complex geometry.

Automatic recognition of contact surfaces and CAD features, reducing manual work.

No geometry cleanup required, streamlining pre-processing.

Assembly Management

Comprehensive tools for handling complex multi-component assemblies efficiently.

Facilitates model organization and connectivity for system-level simulations.

Loads and Boundary Conditions

Intuitive, process-oriented workflows for applying loads and constraints.

Result mapping between meshes (fine-to-coarse or coarse-to-fine) for multi-step or multi-fidelity analysis.

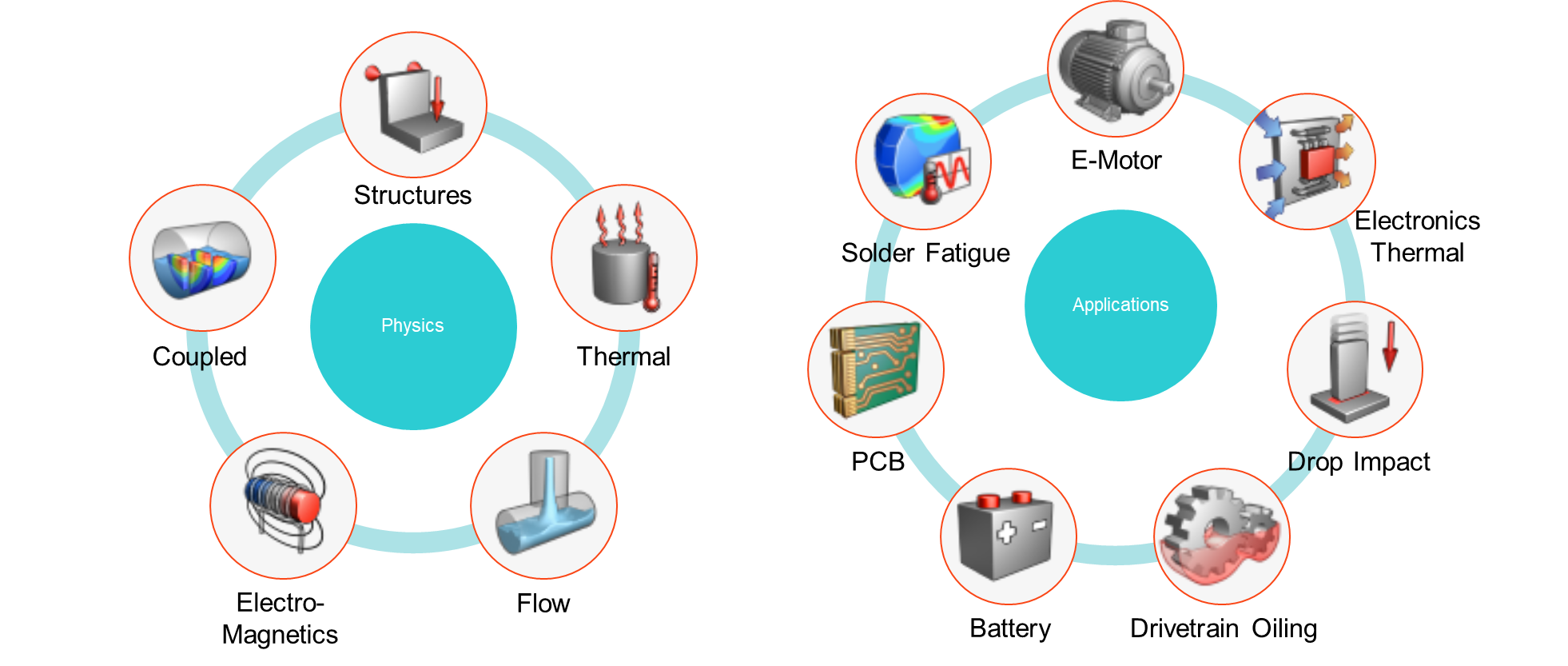

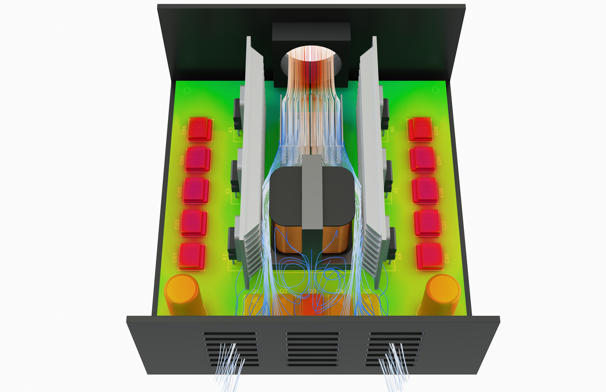

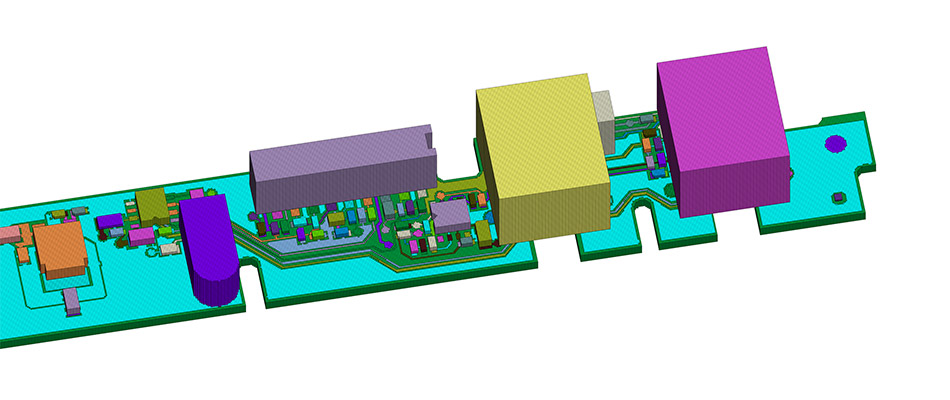

SimLab helps bring Altair’s simulation-driven design philosophy to the electronics industry, inspiring innovation while ensuring timing, performance, reliability, and compliance targets are met. Thermal analyses can be easily performed without requiring advanced CFD knowledge. Automate structural stress, vibration, and drop test performance assessments with robust and repeatable workflows for fast, accurate, and consistent analysis, even for occasional users. Optimize electric motors, taking into account the generated power, noise and thermal considerations of a design.

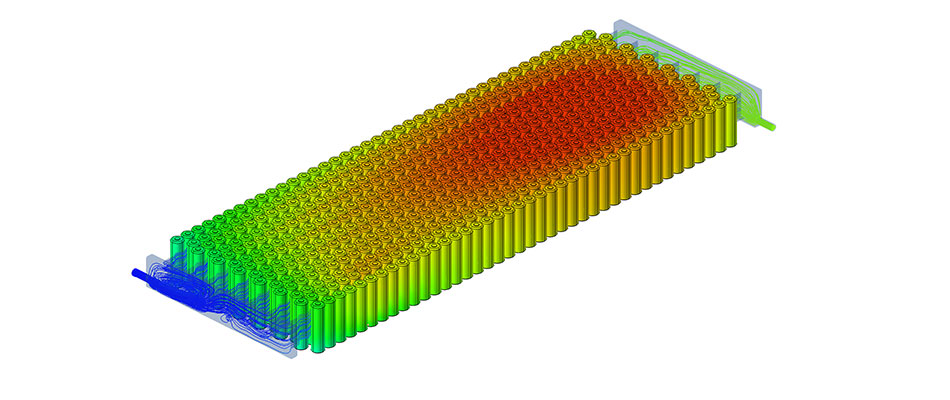

Thermal and Flow Analysis

Simplify the challenges of transient heat transfer and flow dynamics with SimLab. Efficiently simulate scenarios such as gearbox oil, inverter and battery cooling, vehicles navigating through sloshingwater, and the movement of granular particles. Quickly assess the performance of heat sinks and convection heating systems with rapid meshing capabilities and intuitive process-oriented workflows.

With application specific workflows for drop test, fatigue, and structural optimization, SimLab simplifies complex analysis problems. Import an existing CAD geometry, retain parametrization, and automatically mesh to quickly experiment with design variants for an increased understanding of linear static, non-linear static, normal modes, modal frequency response, or small displacement performance.