Feature & Benefits

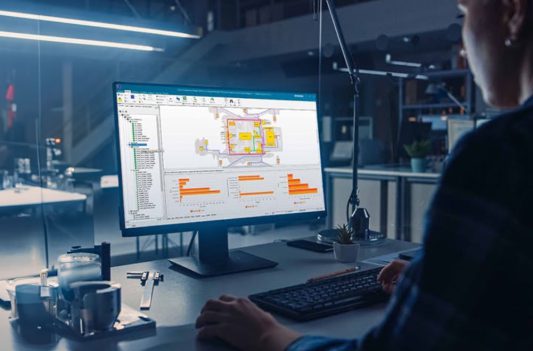

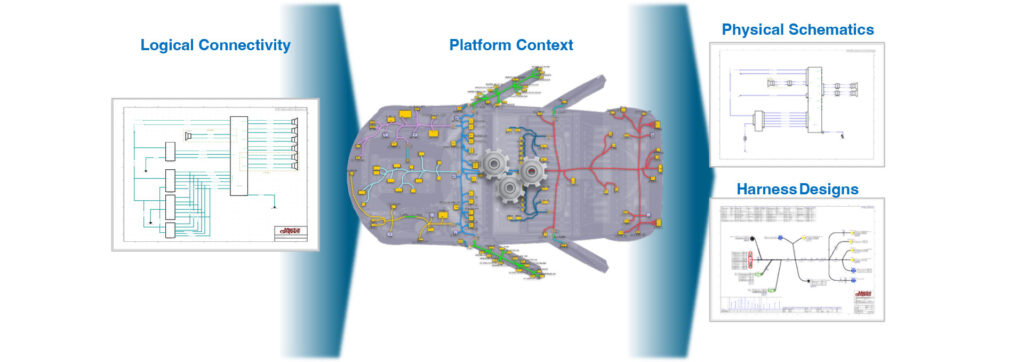

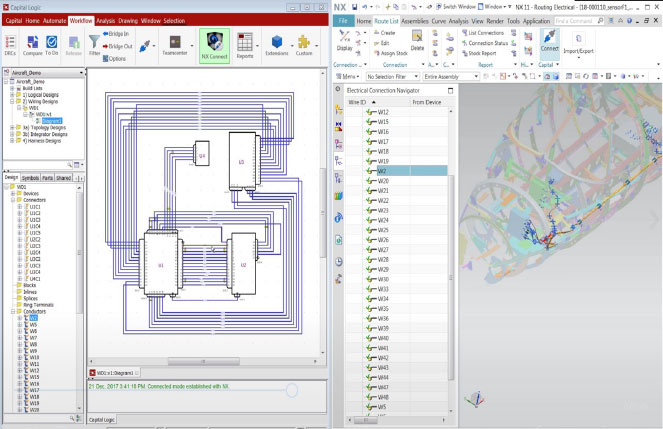

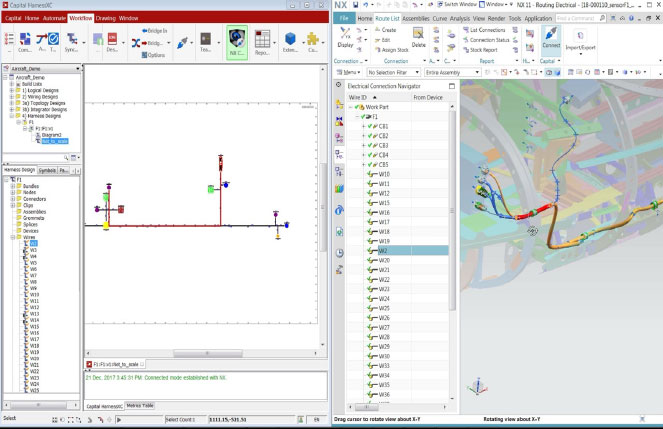

Capital Logic -Schematic tool used for powerful graphical and design process management environment for both logical connectivity designs (signal) & physical wiring design (wires, splices, multicore, etc.)

Capital Harness – Automatically create harness engineering, validation and reporting, harness components to fully create BOM, and also automated Engineering function for calculation

Capital Integrator – automates integration of logical subsystem and physical designs to generate optimized component layout and physical wiring

Benefit

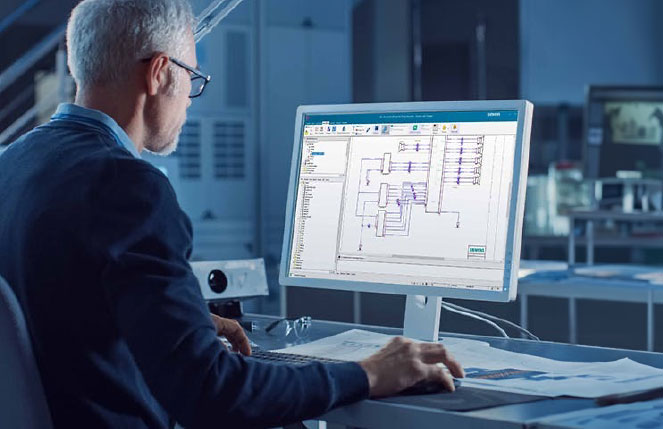

Capital Logic Designer

Create logical and wiring schematic designs

Provide platform-level electrical design and visualization

Leverage Capital Logic Designer to help engineers with early stage platform layout.

Simplify design change and decision making

Allow direct navigation between wiring and topology abstractions.

Automate and control design tasks

Use rules-driven device placement and wire routing. Naming conventions, design rule checks (DRCs) and templates can be defined and automatically applied.

Save time and effort

Provide early indication of wire-routing, bundle diameters and harness complexity. Allow wire lengths to be back-annotated to support accurate voltage-drop, weight and other types of analyses.

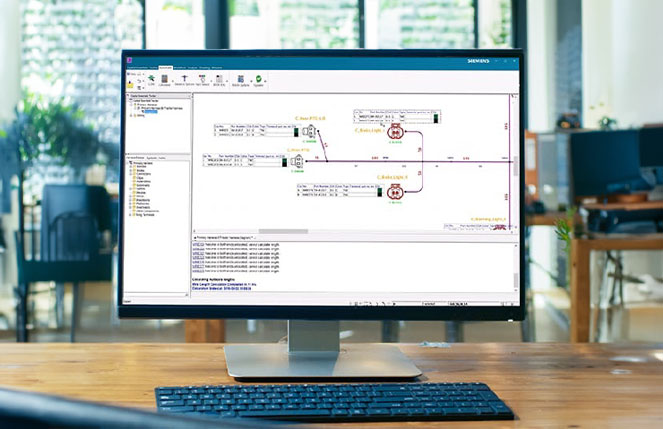

Capital Harness Designer

Create accurate, manufacturing-ready harness designs

Automate validation

Use part selection routines to automatically add wires, multicores, terminals, seals, cavity plugs, tapes, tubes, heat-shrink sleeves and other harness components to create a full manufacturing bill of materials.

Test as you go

Ensure the final design meets your organization’s defined best practices with the provided multiple configurable design rule checks.

Calculate material needs

Leverage automated engineering functions to calculate manufacturing wire lengths, bundle diameters, optimized splice positions, taping quantities, harness weight and other quantities describing the finished design.

Collaborate with design merge

Merge design changes from mechanical computer-aided design (MCAD) and other tools into existing harness designs continuously – without overwriting locally mastered design details and attributes. “Change policies” control how Capital Harness Designer should respond to design changes from multiple sources; the system automatically assesses the design change impact and applies the changes to the harness design.

Ensure consistency with graphical styling templates

Uniquely render multiple graphical representations from the same design via configurable graphical styling templates. Using this feature, you can create reference designs that conform to consistent in-house standards and styles and automatically re-render the design – on demand – into the required styles of your customer/supplier organizations.

Manage multiple harnesses with Option and Variants (OV)

Manage multiple harness variants from a single 150% design. The tool automatically identifies which components are assigned to which variant and compiles the manufacturing bills of material for each.

Direct design changes

Facilitate change processes with the data-centric architecture of Capital. Use multiple change management capabilities, such as tabular and graphical difference reports, version management and compatibility control (build lists).

Define project and process management

Define and apply project norms such as naming conventions, design rule checks, customer options and variants. Process constraints such as release management sequence, design locking, user permissions and component naming can be mandated.

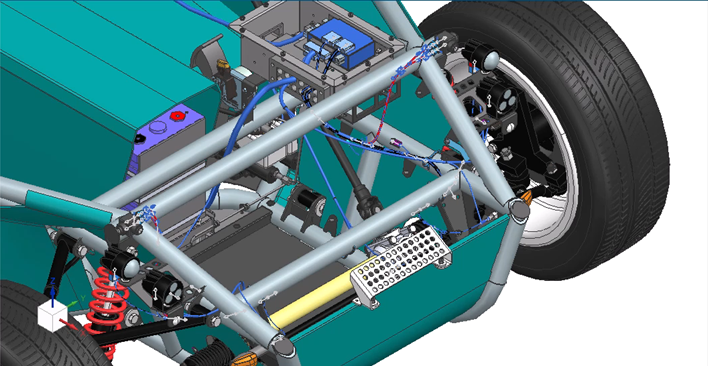

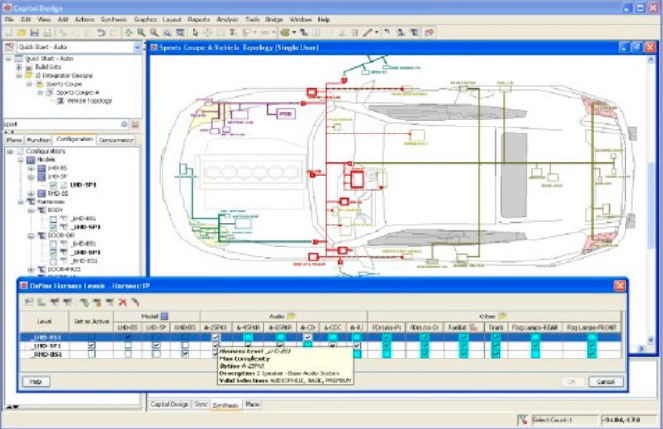

Capital Systems Integrator

Optimize vehicle E/E architecture to minimize cost and weight

Develop the electrical and electronic (E/E) architectures of today’s sophisticated, highly connected and complex vehicles. Employ automatic and manual placement features to provide a powerful device packaging capability.

Analyze platform physical architectures

Simplify the task of subsystem integration with automatic synthesis of wiring objects using configurable rules. This allows real-time wiring architecture studies and ensures the consistent application of intellectual property and engineering best practices.

Promote quality

Leverage user-accessed design refinement functions, such as the ability to insert in-line connectors and move splice locations, to significantly improve the quality of designs.

Save time with Capital

Seamless integration within the Capital software suite provides a data-centric environment with easy access to and from other Capital tools.