Features & Benefits

reduced programming time

Feature-based machining and modern interactive techniques automate NC programming, reducing programming time, standardizing processes, and increasing efficiency.

shorter machining cycles

Achieve faster machining, superior surface quality, and longer tool life with high-performance machining operations.

higher part quality

Complete jobs efficiently and punctually by utilizing CAD/CAM software to seamlessly integrate part manufacturing — from initial 3D models to precision machined parts.

Description

NX CAM Foundation provides the core tools and functionalities essential for any CNC programmer using NX CAM. It streamlines program creation with data translators, visualization, toolpath editing, postprocessing, and shop documentation capabilities. While its primary focus is programming, it also offers basic design tools and integrates with Teamcenter for enhanced collaboration and data management, making it valuable for other manufacturing roles.

Who Uses NX CAM?

NC programmers, manufacturing engineers, production managers, and companies of all sizes that utilize CNC machining for part production can benefit from using NX CAM.

CAM Capability

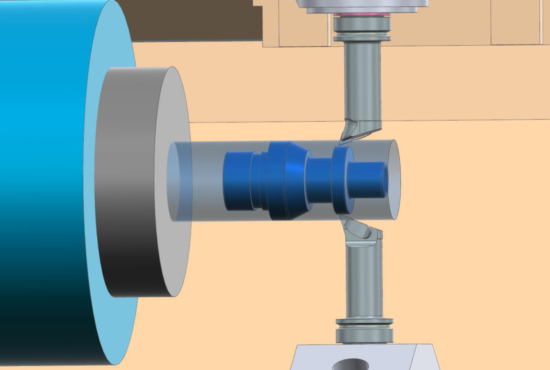

2.5 Axis

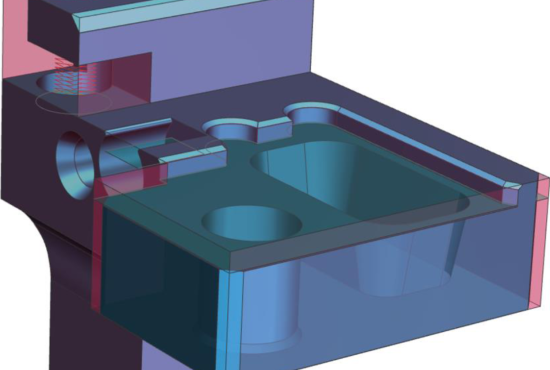

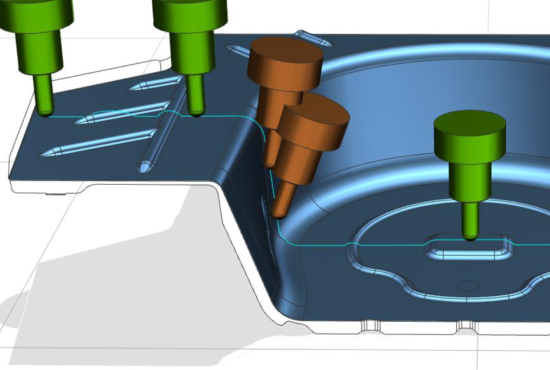

NX CAM’s volume-based 2.5D milling enables fast, intuitive programming of prismatic parts. It offers automatic volume calculation, instant cut previews, and material tracking with IPW.

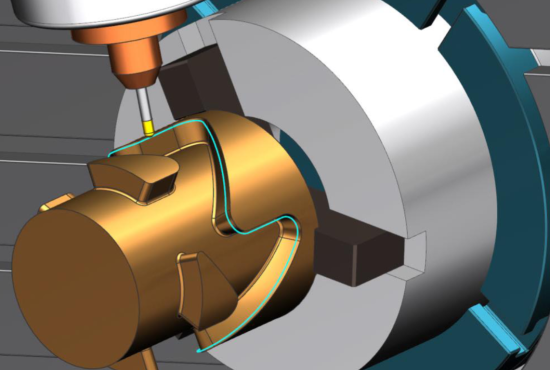

3 Axis

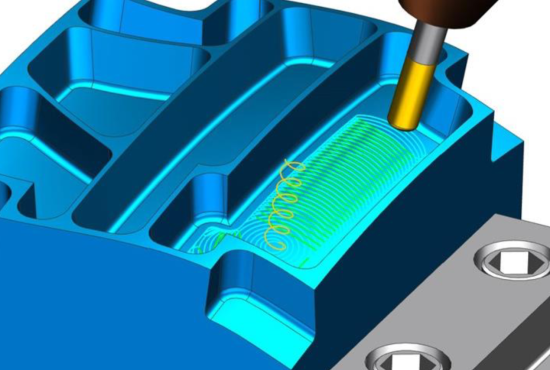

NX CAM’s 3-to-5 axis toolpath conversion enhances machining efficiency and precision. The software automatically avoids holder collisions, allows for the use of shorter tools to minimize vibration, and is available for 3-axis finishing and roughing operations, making it ideal for complex parts like molds and dies.

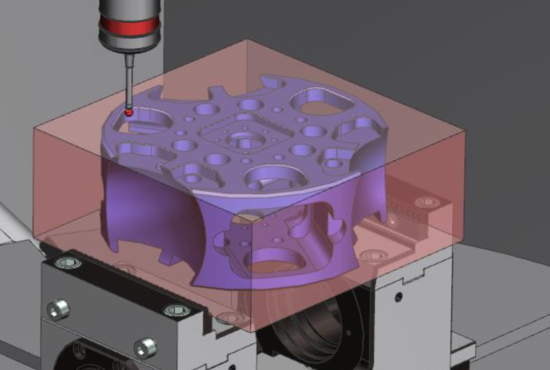

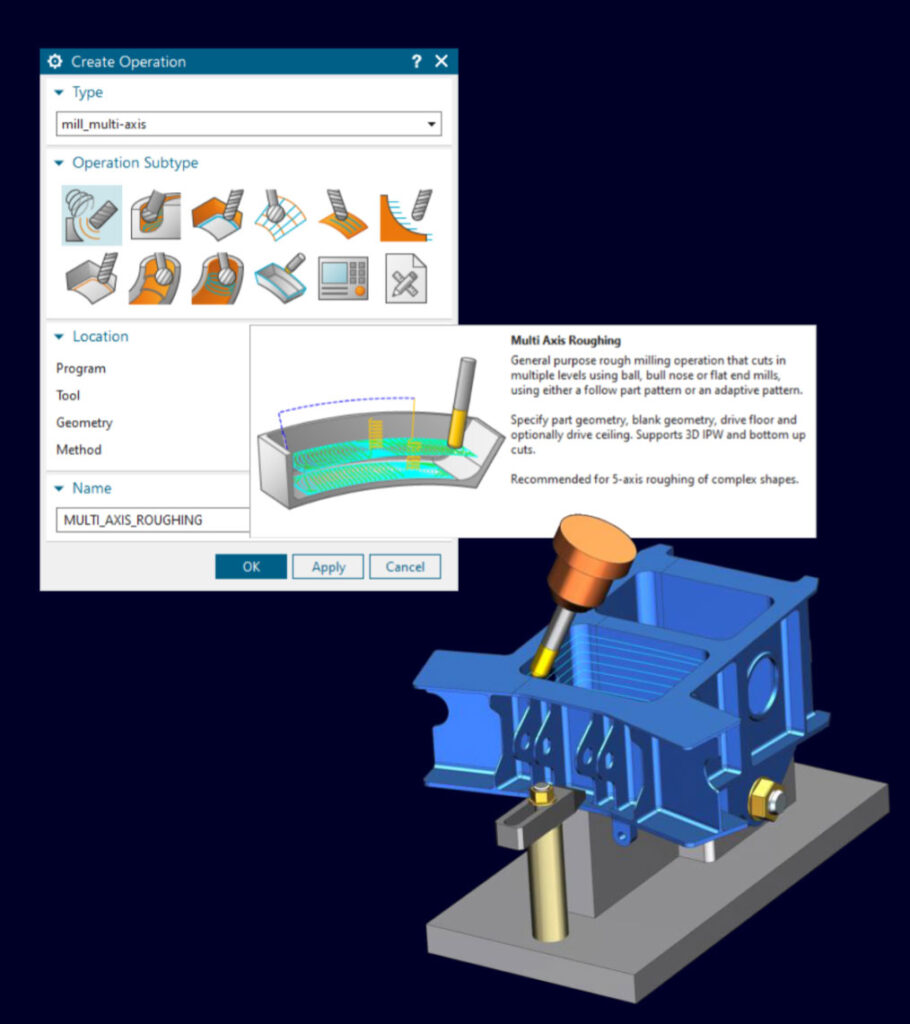

5 Axis

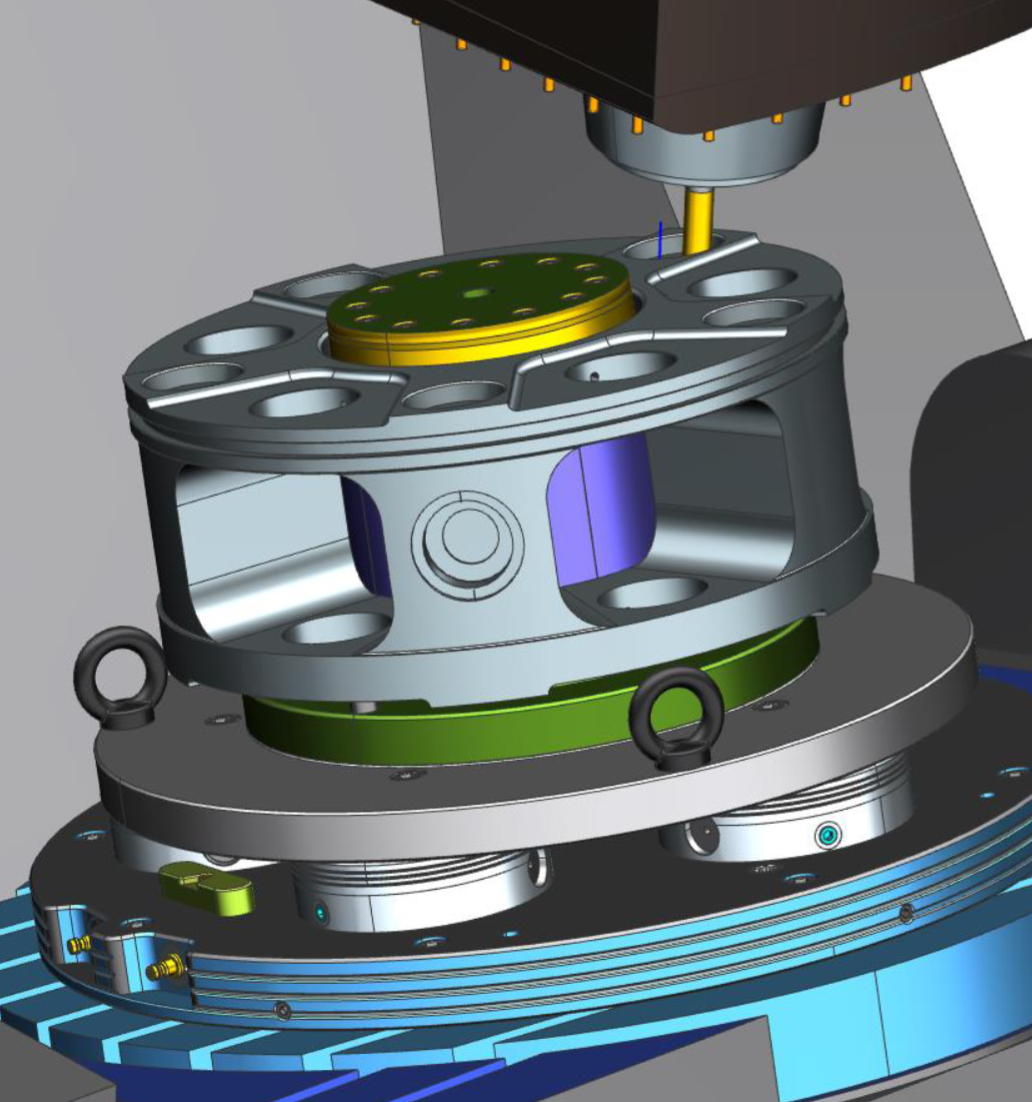

Advanced machining strategies, 5-axis roughing reduces heat generation and vibration in the cutting zone, extending tool life. Z-level machining, Guiding curve toolpath is an ideal cutting strategy for multi-axis high speed machining

Multi-axis Deburring

The software automatically defines and applies advanced settings to precisely manage the cutting strategy, ensuring smooth and secure toolpaths for optimal machining efficiency.