Key Features and Capabilities

1. Advanced Scheduling Algorithms

Optimized production schedules and maximize efficiency and minimize downtime by considering

- Machine Capacities Material Availability

- Labor Constraints

- Setup Times

- Order Priorities

2. Integration with Enterprise Systems

Integration with Enterprise Systems

- ERP and MES systems

- Ensuring synchronized production schedules with business objectives

- Enabling real-time data exchange for better decision-making

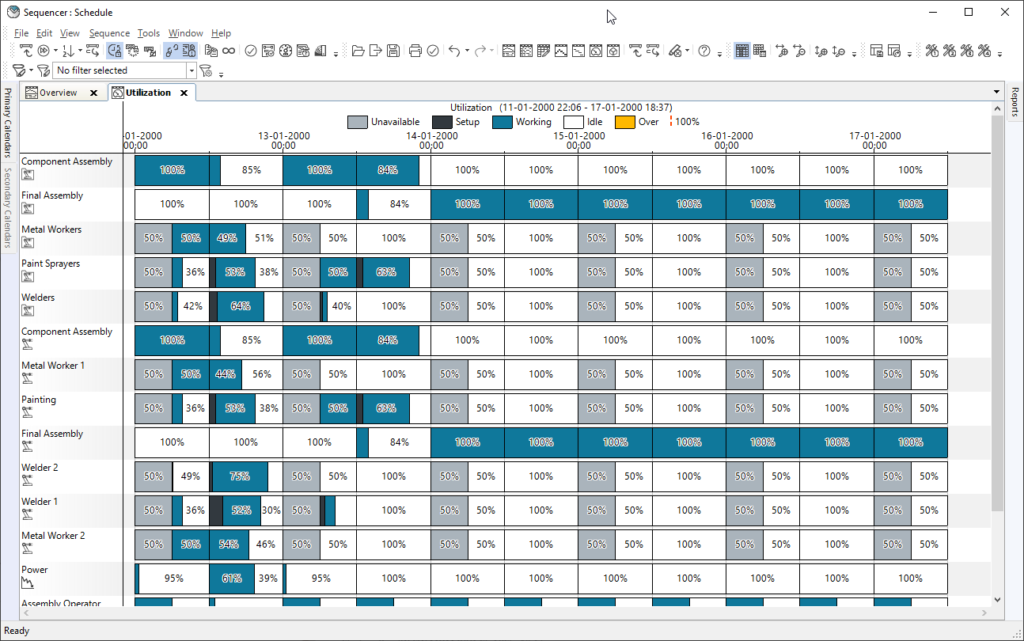

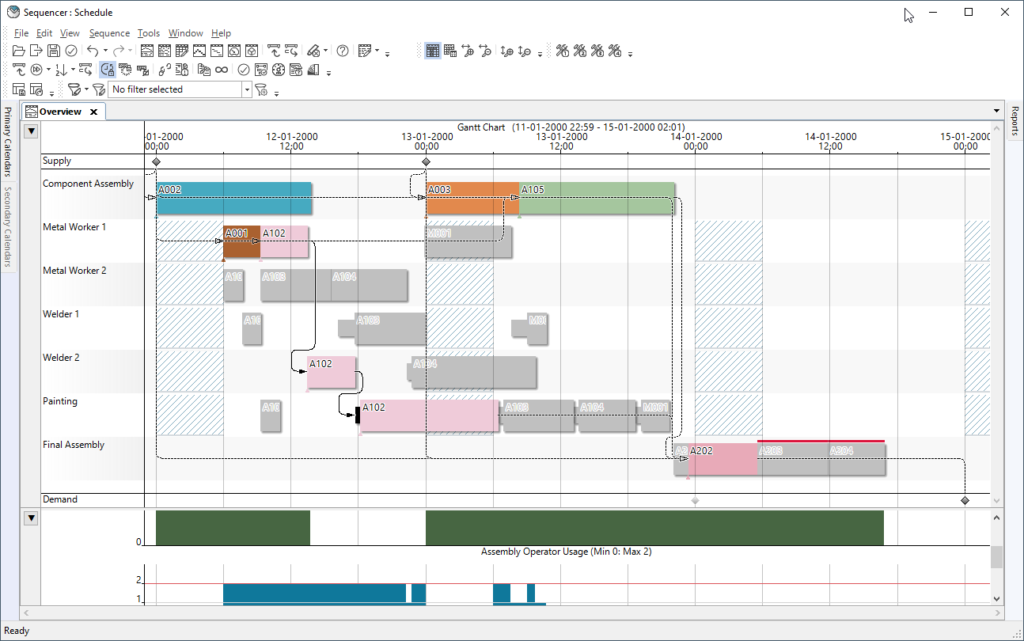

3.Visualization Tools

Opcenter Scheduling offers intuitive visualization tools like

- Gantt charts, allowing planners to view, analyze, and adjust production schedules to optimize resource use and production flow

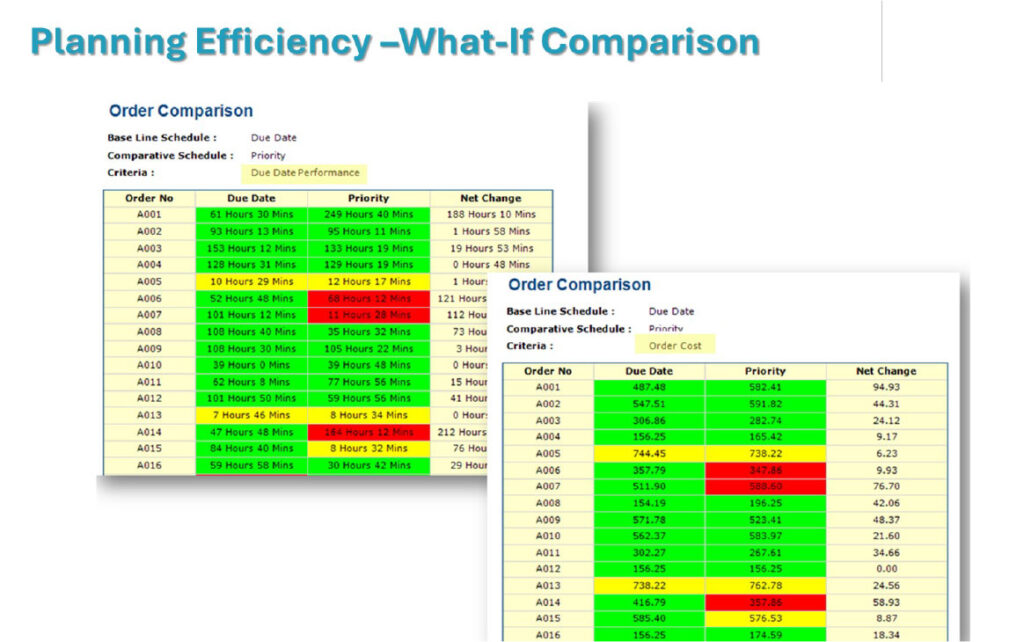

4. Scenario Analysis and What-If Simulations

Users can perform scenario analysis and what-if simulations

- Helping planners evaluate different scenarios

- Identify potential issues

- Explore alternative scheduling options for informed decision-making

5.Resource Optimization

The software optimizes

- Resource allocation and utilization

- Balancing workloads and minimizing idle time to maximize productivity and throughput while maintaining quality

6.Flexibility and Customization

Opcenter Scheduling is flexible and customizable

- Supporting configurable rules, workflows, and user-defined parameters to meet the needs of various manufacturing industries and production environments

7.Compliance and Traceability

For regulated industries like aerospace and pharmaceuticals, Opcenter Scheduling offers features for tracking and documenting schedules to ensure compliance and facilitate audits

8.Real-Time Monitoring and Alerts

The software provides

- Real-time monitoring to track production progress

- Ensure schedule adherence

- Alert users to deviations

- Helping maintain efficiency

- Quickly address disruptions

Description

Industry Applications:

Opcenter Scheduling is widely used across various industries including

- Automotive

- Aerospace

- Electronics

- Pharmaceuticals

- Consumer goods

- Discrete manufacturing sectors

It caters to both make-to-order and make-to-stock production environments, supporting complex scheduling requirements and helping manufacturers meet customer demands effectively.

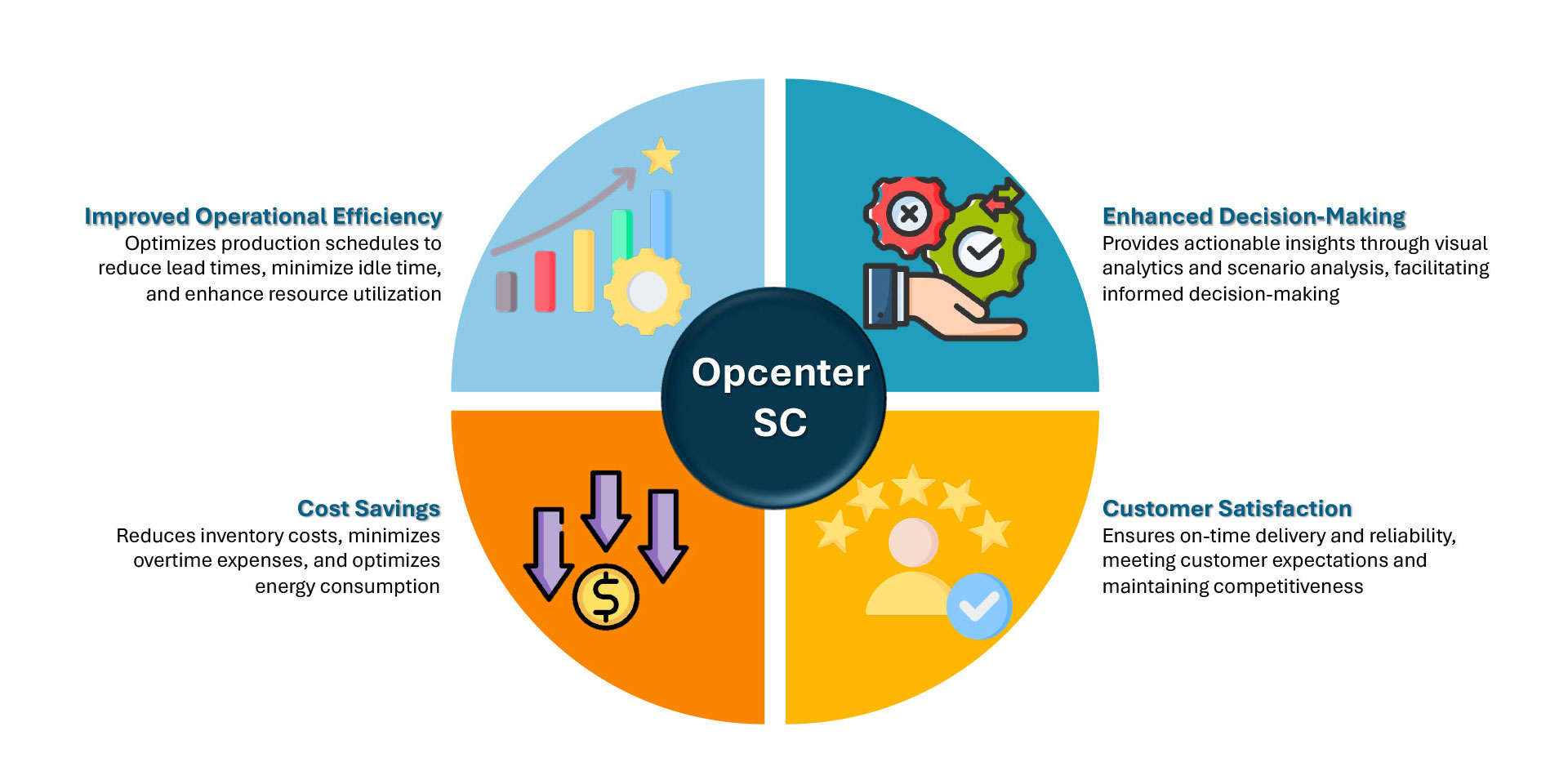

In summary, Opcenter Scheduling empowers manufacturing companies to achieve operational excellence by

- Optimizing scheduling processes

- Improving productivity

- Aligning production activities with strategic business goals

Start your free, 30-day trial in minutes

Trials: : https://trials.sw.siemens.com/en-US/trials/opcenter-scheduling-standard