Key Features and Capabilities

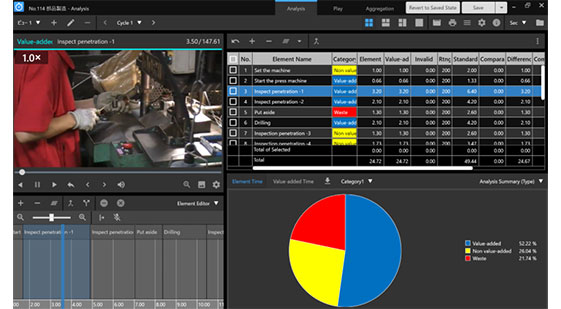

- Motion Analysis:

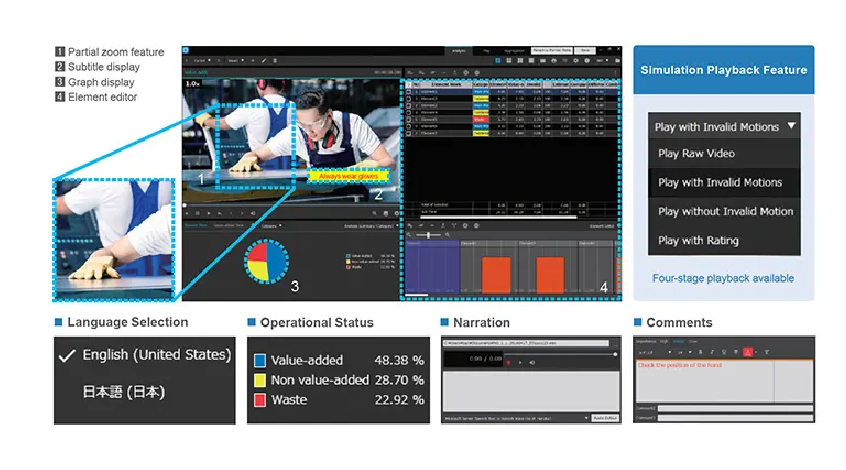

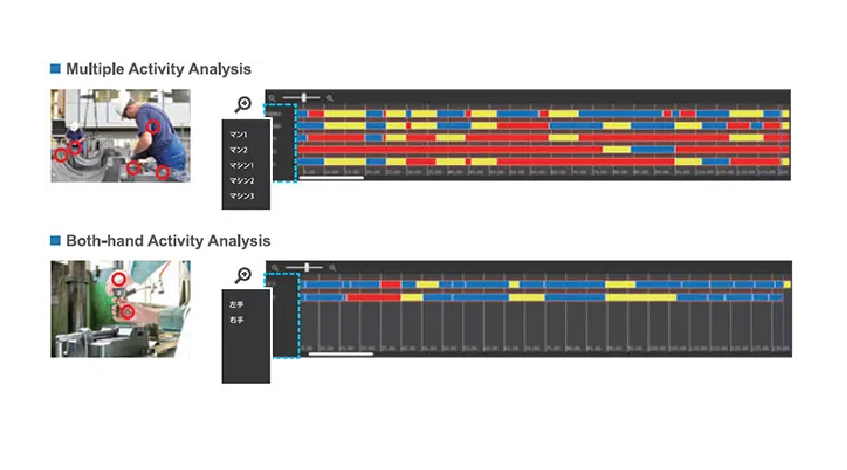

- OTRS allows for the capture and analysis of worker movements during tasks using video recordings.

- It identifies and evaluates individual motions, gestures, and actions performed by workers to understand workflow efficiency and ergonomic considerations.

- Time Analysis:

- The software measures and analyzes the time taken for each task component or motion captured in the video recordings.

- It breaks down tasks into segments to identify bottlenecks, inefficiencies, and opportunities for improvement in time management.

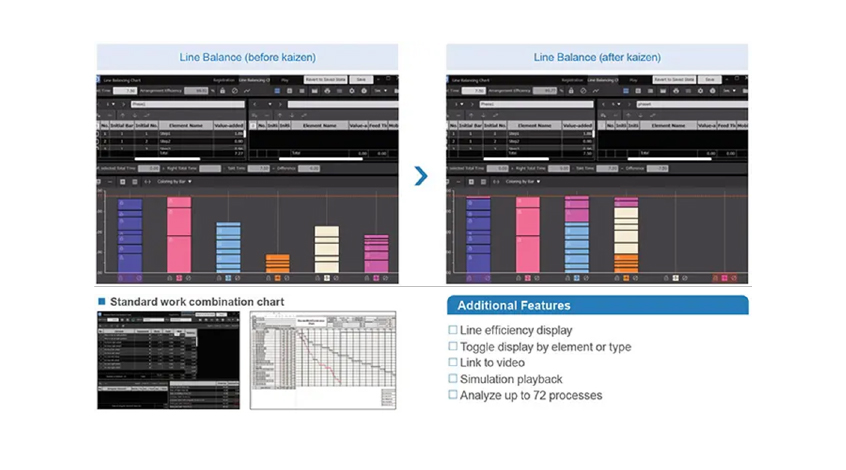

- Productivity Optimization:

- Based on the analysis, OTRS suggests improvements to optimize workflow and reduce unnecessary movements or delays.

- It aims to standardize processes and best practices to maximize productivity and minimize non-value-added activities.

- Cost Reduction:

- By identifying inefficiencies and optimizing workflows, OTRS helps in reducing labor costs, production costs, and overall operational expenses.

- It facilitates better resource allocation and utilization, leading to cost savings over time.

- Ergonomic Improvement:

- OTRS considers ergonomic factors by analyzing worker movements and recommending adjustments to workstations or processes to enhance safety and comfort.

- This helps in reducing workplace injuries and improving employee satisfaction.

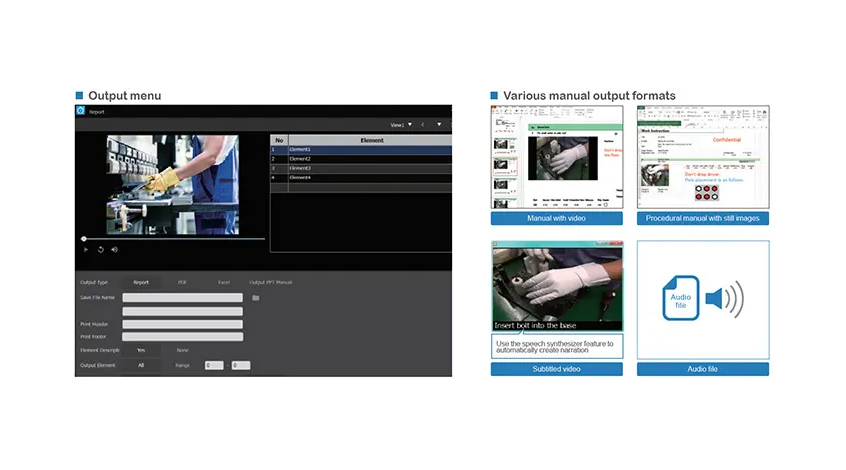

- Reporting and Visualization:

- The software provides comprehensive reports, visualizations, and analytics based on the motion and time analysis data.

- Managers and analysts can review detailed insights to make informed decisions for process improvement and optimization initiatives.

Benefits

Efficiency Improvement: Streamlines work processes, reduces idle time, and enhances overall operational efficiency.

Cost Savings: Optimizes resource allocation, reduces labor costs, and minimizes production and manufacturing expenses.

Quality Enhancement: Improves product or service quality by eliminating errors and standardizing procedures.

Safety and Compliance: Enhances workplace safety and ensures compliance with ergonomic standards and regulations.

Description

OTRS leverages Industrial Engineering to support your company optimize work processes on site.

OTRS is a specialized software solution that utilizes video-based motion and time analysis to optimize work processes, reduce costs, and improve productivity in manufacturing and production environments. It leverages detailed data insights to drive continuous improvement and operational excellence.