Process Simulate Human

Using digital human modeling throughout the product lifecycle to achieve continual improvement

Benefits

- Use digital human modeling throughout the product lifecycle to achieve continual improvement

- Optimize your designs for friction-free human interaction

- Use a comprehensive suite of analysis tools to identify potential risk factors

- Effectively communicate issues and visualize potential solutions

- Leverage virtual reality and motion tracking technologies for even deeper design analysis

Features

- Global anthropometric databases to accurately model your populations

- State-of-the-art task simulation engine to generate simulations using high-level commands

- One of the most comprehensive set of human performance tools available on the market today

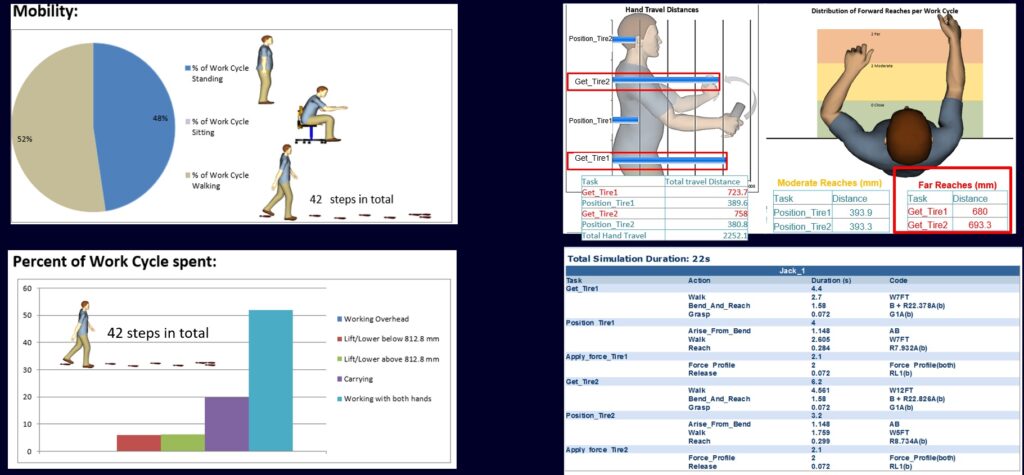

Ergonomic analysis tools

- Posture assessment (OWAS, RULA)

- Lifting guide (NIOSH)

- Posture monitor (customizable values)

- Eye views

- Whole body and arm strength (SSP, AFF)

- Metabolic energy and fatigue accumulation

- Static and cumulative low back demands

Creating simulation and ergonomic analysis The task simulation builder accepts high-level commands to instruct a human model in your 3D virtual environment. This capability facilitates quick animation and scenario development. Once a task sequence has been defined for the human model, you can test what-if scenarios by swapping in human figures of different sizes, changing the position of objects, or modifying the forces associated with tasks. Human postures and motions are automatically recomputed in response to the updated configuration. The task simulation builder provides extensive ergonomic reporting and estimates based on standard timetables.

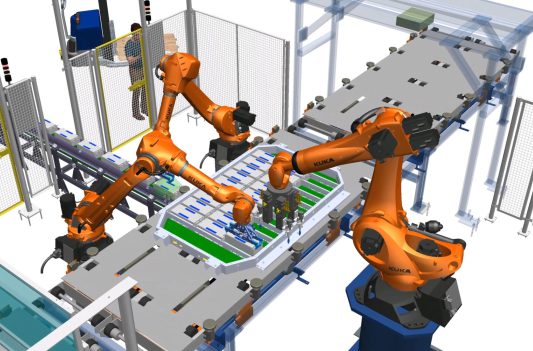

Robotic Process Simulate

The business value of Process Simulate The increased complexity of products and manufacturing processes presents world-class manufacturers with “time-to-market” and asset optimization challenges. Manufacturing engineering teams are expected to enable flawless new product launches and adhere to cost, quality and start-of-production targets. To meet these challenges, leading manufacturers leverage their organizational knowledge and the availability of 3D models of products and resources to virtually validate their manufacturing processes upfront. With new evolving technology, thousands of validation experiments can be conducted efficiently and almost automatically to ensure upfront production optimization.

Benefits

- Reduce cost of change with early detection and communication of product

design issues - Reduce number of physical prototypes with upfront virtual validation

- Optimize cycle times through simulation

- Ensure ergonomically safe processes

- Reduce cost by re-using standard tools and facilities

- Minimize productions risk by simulating several manufacturing scenarios

- Early validation of the mechanical and electrical integrated production processes (PLC and robotics) Early validation of production commissioning in a virtual environment

- Increase process quality by emulating realistic processes throughout the

process lifecycle

Features

- 3D simulation

- Static and dynamic collision detection

- 2D and 3D sections

- 3D measurements

- Sequencing of operations

- Assembly and robotic path planning

- Resource modeling (3D and kinematics)

- Documentation tools

- Natively supported JT™ visualization

Standard

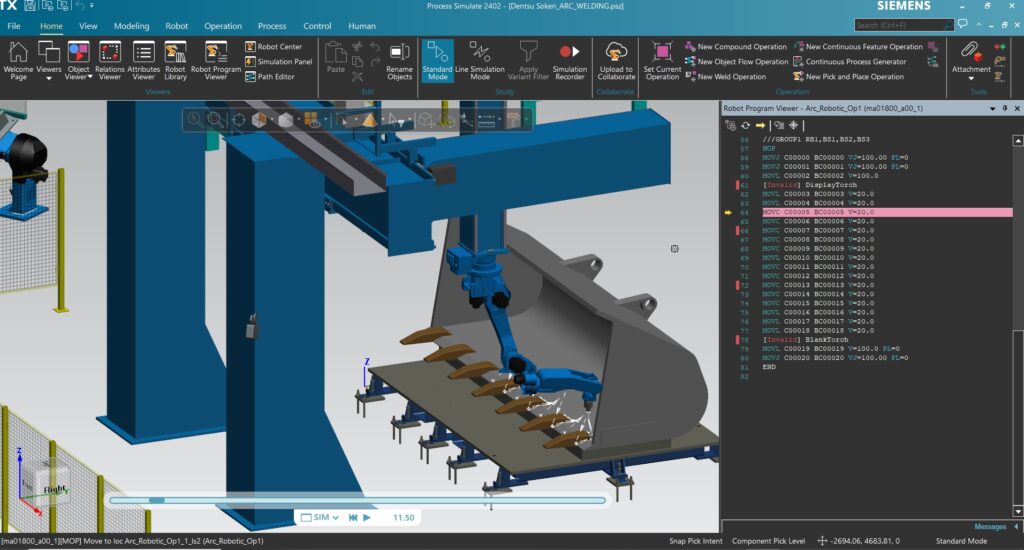

OLP — offline programming

Maintain and optimize robotic processes in a dynamic 3D virtual environment without interrupting existing production.

Use Process Simulate Offline Programming (OLP) for the creation and manipulation of robot-specific target locations, orientation, configuration, motion paths and interference zones. Perform cycle time optimization, configurable motion and OLP command creation and editing, robot calibration, and complete robot program download and upload based on the robot teach pendant interface and the robot controller for all major robot brands.

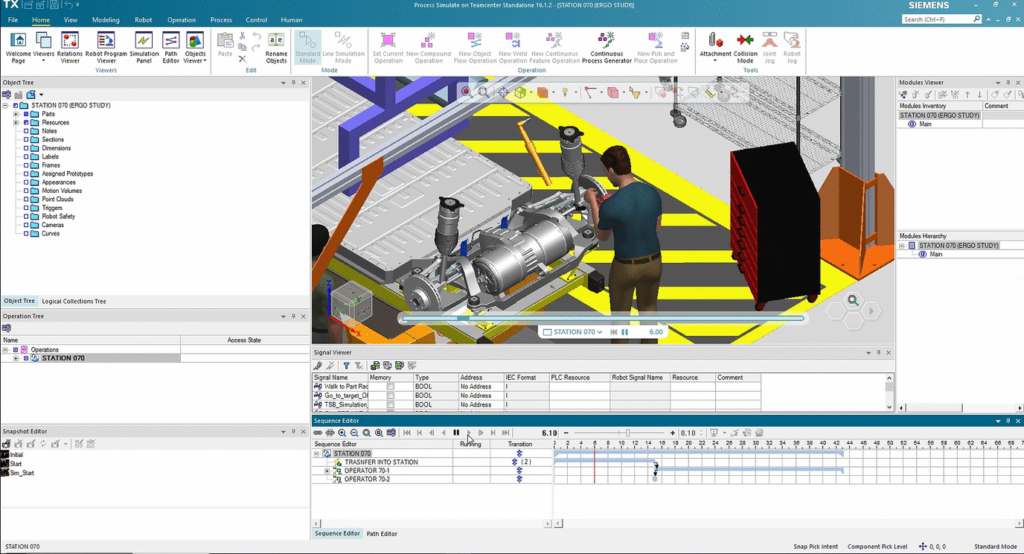

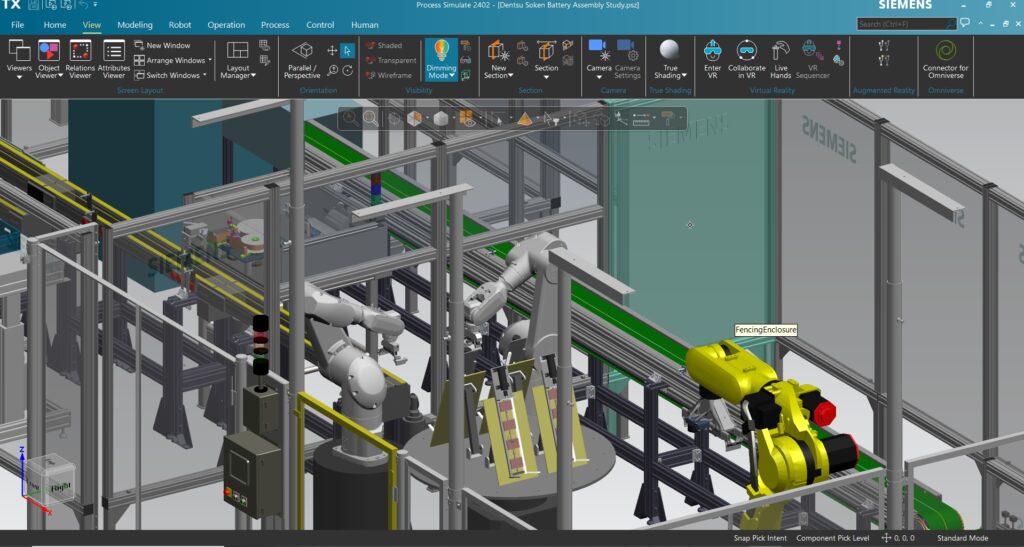

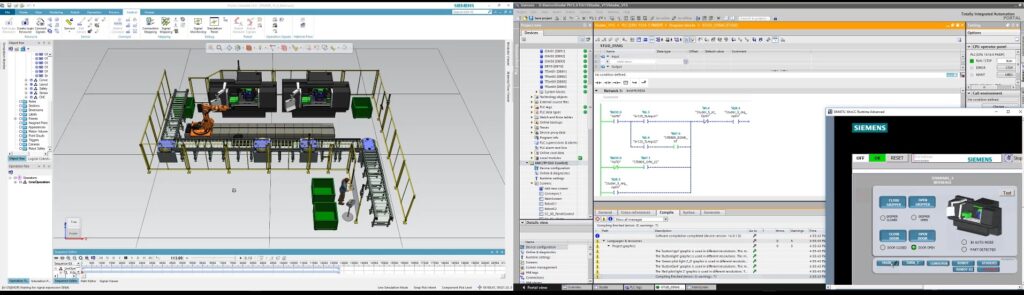

VC Lite — virtual commissioning

Perform virtual commissioning (VC) with offline Process Simulate models, including layout creation, kinematics definitions, simulation and analysis.

Use Process Simulate VC Lite to validate and optimize the build, installation and commissioning (mechanical and electrical)

of manufacturing zones or cells containing robots and other automation devices. Simulate real programmable logic controller (PLC) code

with the hardware using Siemens TIA Portal and PLCSIM Advanced software or OPC UA software and the actual robot programs,

providing the most realistic virtual commissioning environment.

Continuous Manufacturing

Develop robotic manufacturing processes with tools for weld seam creation and continuous path generation for gluing, sealing and spraying operations, full robot motion path simulation and optimization for robot placement, reach and cycle time.

Use Process Simulate Continuous Manufacturing to import weld seams and machining toolpaths for robot path creation, to generate weld seams and continuous motion paths based on curves and geometry recognition, to align path locations based on surface-normal conditions, and to simulate paint and spray coverage and thickness.

Summary :

- Process Simulate is a digital manufacturing solution for manufacturing process

- verification in a 3D environment. Process Simulate is a major enabler of speed to-

- market by allowing manufacturing organizations to virtually validate manufacturing

- concepts upfront – throughout the lifecycle of new product introductions.

- The ability to leverage 3D data of products and resources facilitates virtual

- validation, optimization and commissioning of complex manufacturing

- processes, resulting in faster launch and higher production quality.