Key Improvements in Productivity

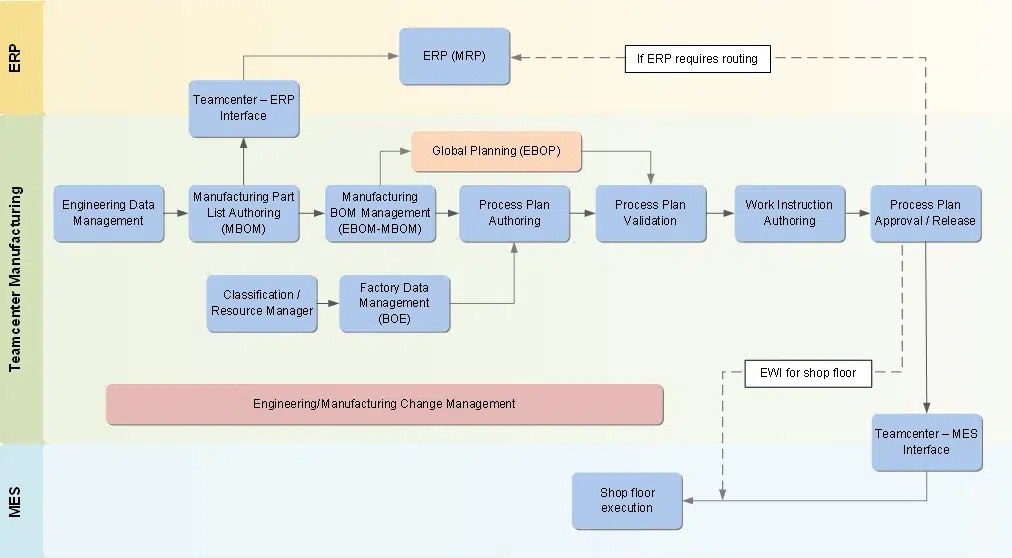

Teamcenter Manufacturing enhances productivity through several key functionalities and benefits that streamline manufacturing processes and improve overall efficiency:

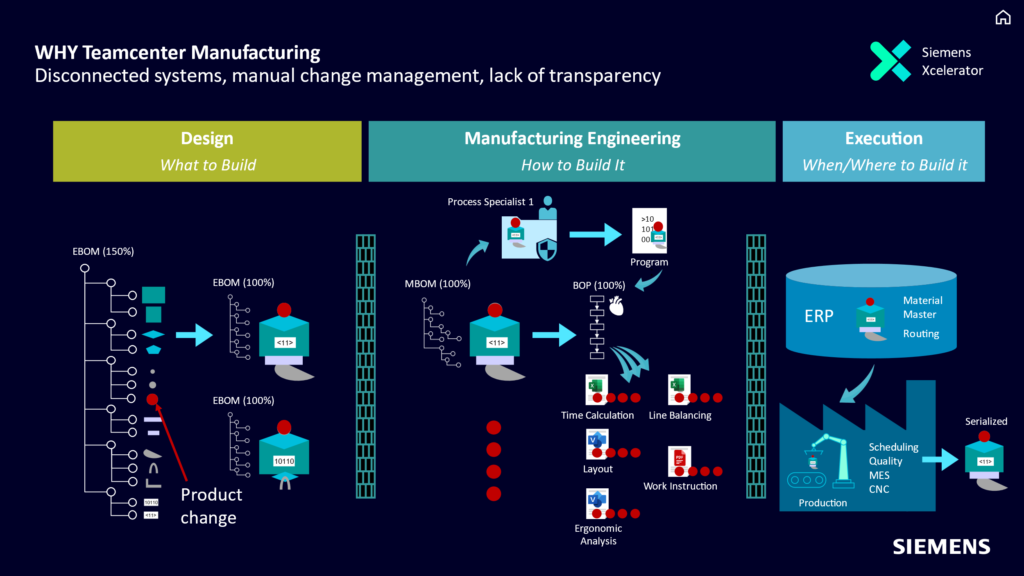

- Centralized Data Management:

Teamcenter provides a single source of truth for all manufacturing-related data, including Manufacturing Bills of Materials (MBOM) and Bills of Processes (BOP). This centralization ensures that all stakeholders work with the most current and accurate information, reducing errors and rework. - Automated Workflows:

By automating complex manufacturing processes and workflows, Teamcenter minimizes manual tasks and accelerates time-to-market. This automation helps to eliminate bottlenecks and enhances overall process efficiency.

- Enhanced Collaboration:

Teamcenter fosters seamless collaboration between engineering, manufacturing, and quality teams. This cross-functional collaboration allows for rapid decision-making and issue resolution, which is crucial in a fast-paced manufacturing environment. - Improved Change Management:

The platform includes robust change management capabilities that streamline the approval processes for engineering changes. This ensures that all relevant documentation and processes are updated in real-time, reducing the risk of costly errors during production. - Visibility and Control:

Real-time access to manufacturing data and integration with shop floor systems provide comprehensive visibility into operations. This visibility supports data-driven insights that can lead to better decision-making and resource allocation.

- Document Approvals and Routing:

Teamcenter automates the approval processes for documents, reducing the time spent on manual data entry and chasing approvals. This includes managing engineering change requests (ECR) and engineering change notices (ECN) workflows electronically. - Bill of Materials (BOM) Management:

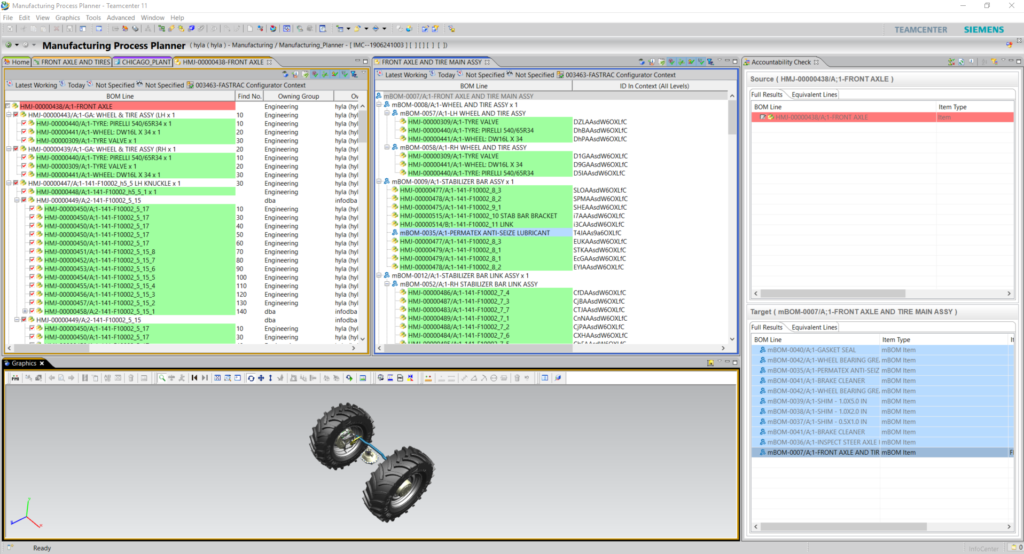

The software can automatically generate Manufacturing Bills of Materials (MBOM) based on the latest product designs, eliminating the need for manual creation and ensuring accuracy.

Specific Tasks Automated by Teamcenter Manufacturing

- Centralized Data Management:

Teamcenter provides a single source of truth for all manufacturing-related data, including Manufacturing Bills of Materials (MBOM) and Bills of Processes (BOP). This centralization ensures that all stakeholders work with the most current and accurate information, reducing errors and rework. - Automated Workflows:

By automating complex manufacturing processes and workflows, Teamcenter minimizes manual tasks and accelerates time-to-market. This automation helps to eliminate bottlenecks and enhances overall process efficiency.

https://www.indx.com/en/product/siemens-teamcenter-manufacturing

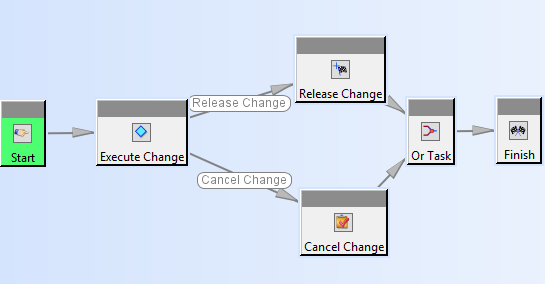

- Change Management:

Teamcenter automates change management processes, ensuring that all stakeholders have access to the latest information and that changes are tracked and documented systematically. This includes revision control and maintaining version history.

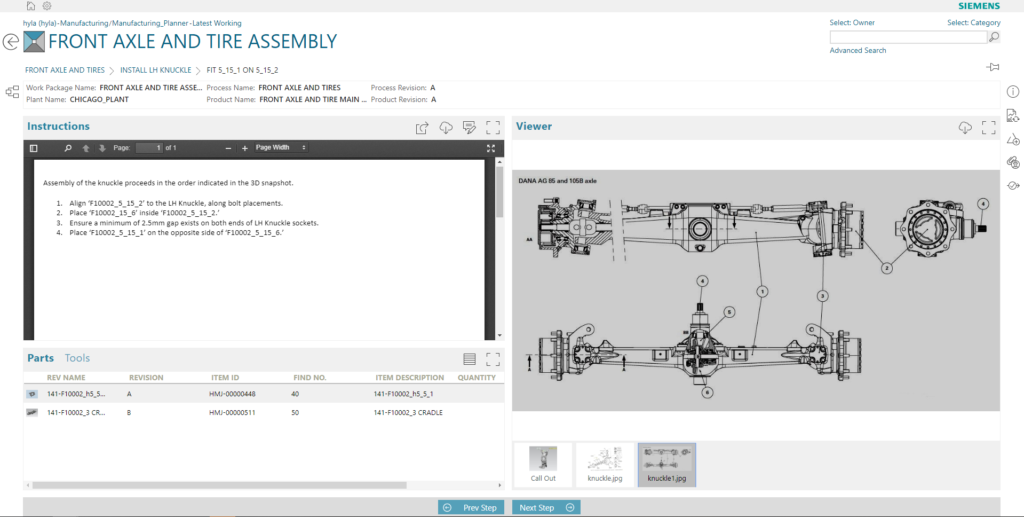

- Electronic Work Instructions (EWI):

It allows for the automatic generation of comprehensive manufacturing work instructions, which can be updated in real-time to reflect changes in processes. This includes the use of 2D and 3D visualization tools to enhance clarity.

https://www.indx.com/en/product/siemens-teamcenter-manufacturing

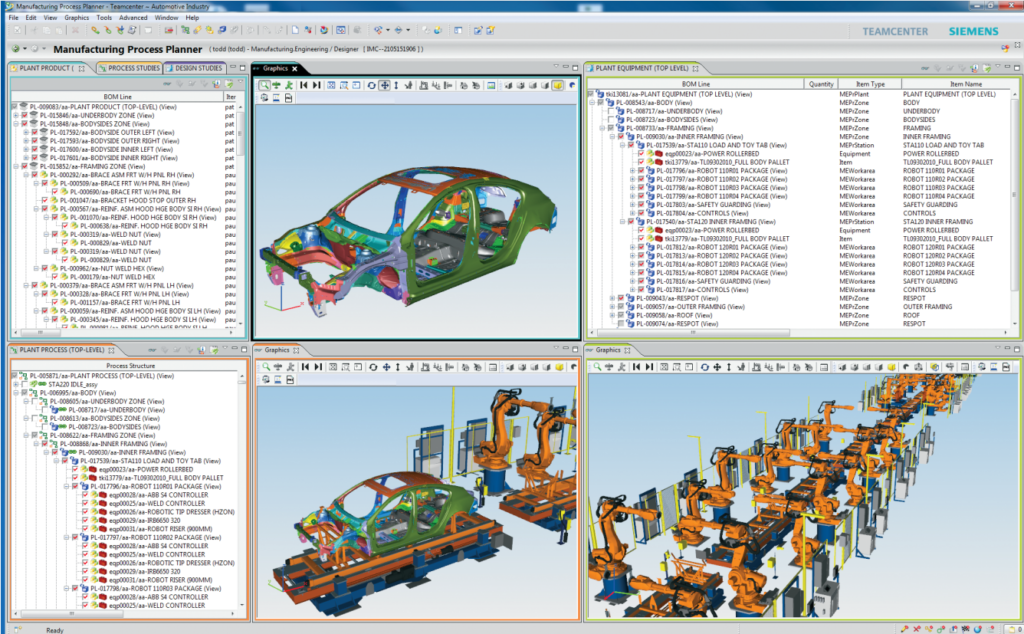

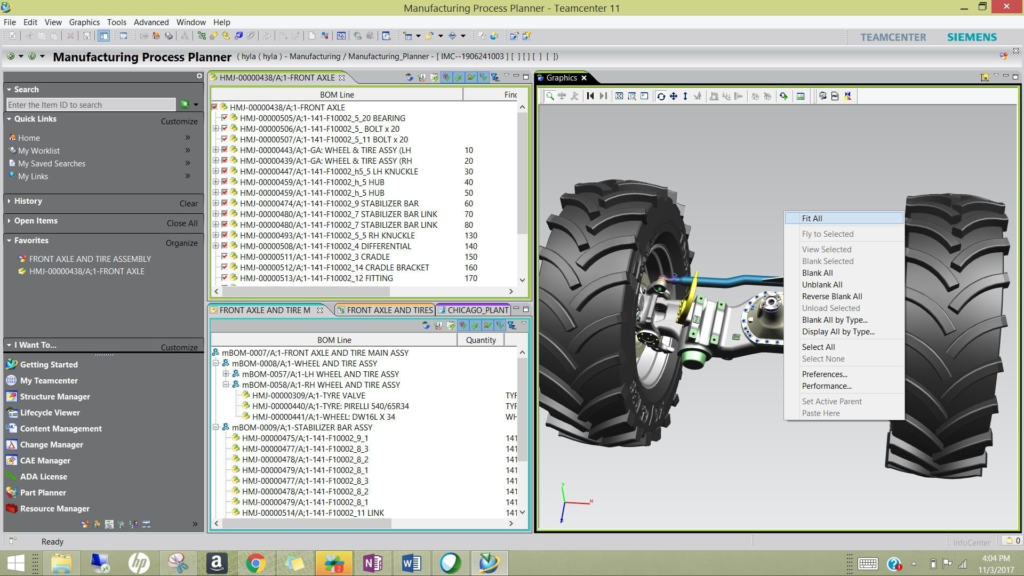

- Manufacturing Process Planner (MPP):

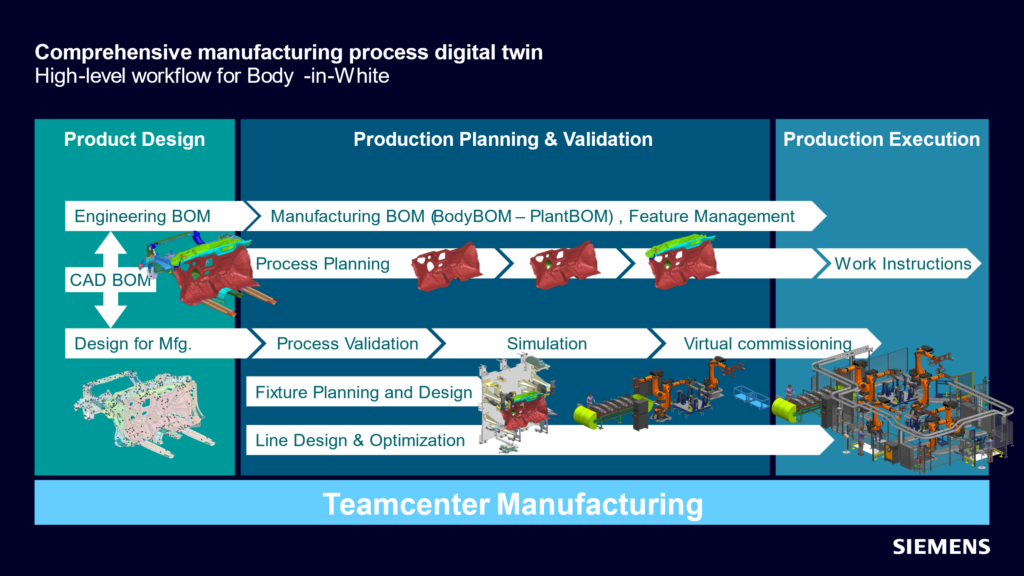

Teamcenter facilitates the automation of manufacturing process planning, synchronizing product engineering with manufacturing activities. This includes creating and managing the Bill of Processes (BOP), which outlines the sequence of operations required for production.

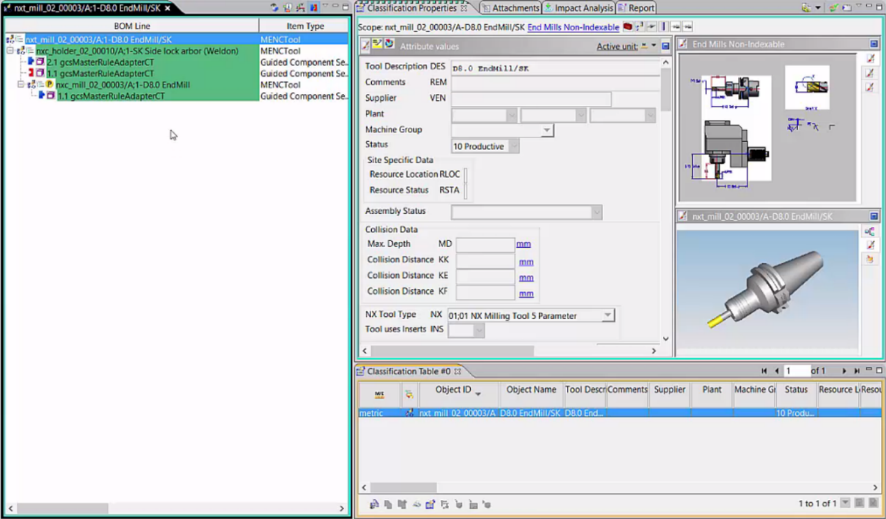

- Manufacturing Resource Library (MRL):

The system automates the assignment of resources and tools needed for manufacturing operations, pulling data from a centralized manufacturing resource library (MRL) to streamline operations.

- Time Management and Analysis:

Teamcenter includes features for automating time management and line balancing, allowing manufacturers to analyze value-added and non-value-added activities efficiently. This helps optimize production schedules and resource allocation. - Integration with Shop Floor Systems:

The software connects with shop floor execution systems (MES), automating the delivery of work instructions and other essential data to the production floor, which enhances real-time data collection and visibility.

By automating these tasks, Teamcenter Manufacturing not only improves productivity but also enhances collaboration, accuracy, and responsiveness within manufacturing operations.

Key features and benefits of Teamcenter Manufacturing include:

- Concurrent development of product and manufacturing planning, ensuring manufacturing constraints are reconciled during product design

- Collaboration framework that connects design, engineering, manufacturing, plants, and suppliers into a virtual enterprise

- Evaluation of alternative manufacturing scenarios to optimize throughput and maximize resource utilization

- Centralized management of manufacturing data, processes, resources, and plant information in a single environment

- Integration with digital twin technology for simulation and validation of manufacturing processes

- Scalability and customization to suit the needs of small and large manufacturing companies

- Improved communication, document sharing, and collaborative decision-making for manufacturing process planning teams

- Integration with other PLM and ERP systems for seamless data flow between product development and manufacturing

Teamcenter Manufacturing offers several modules, including Manufacturing Process Planner (MPP), Process Simulate, Manufacturing Resource Library (MRL), and Active Workspace. These tools enable manufacturers to define manufacturing processes, allocate resources, simulate assembly operations, and communicate instructions to the shop floor. By providing a centralized platform for managing manufacturing data and processes, Teamcenter Manufacturing helps manufacturers accelerate new product introductions, shorten time-to-production, and quickly react to changes throughout the design and build process.

Conclusion

Overall, Teamcenter Manufacturing significantly improves productivity by centralizing data, automating workflows, enhancing collaboration, and providing real-time visibility into manufacturing operations. These features enable manufacturers to streamline processes, reduce costs, and respond more effectively to market demands, ultimately leading to a more efficient manufacturing environment.