Validate production line with Digital Twin, no more testing in actual production line.

For SME factories, the reality is clear: limited budget, limited people, and you can’t afford downtime. Moving machines, changing layouts, or adding an AGV can be riskier than rewarding if decisions are driven by feeling rather than data. This is why our service: Siemens Tecnomatix Plant Simulation—a production system simulation software—is designed for SMEs to test, compare, and validate improvement ideas in a virtual environment – Digital Twin before making changes on the shop floor.

Pain Points for SMEs

- Waste time to create simulation model Delay time to analyst the problem

- The team has no time / a programmer to create simulation scenario (SimTalk)

- No evidence for analytical outputs (bottlenecks, costs, optimal layout) to make fast and right decisions.

Why Use Plant Simulation (for SMEs)

- Lower risk + Higher confidence: simulate the flow of materials, machines, people, and logistics on a computer before making a decision.

- See bottlenecks clearly: know precisely where to fix for the best return—no guesswork.

- Instant what-if testing: if you add a machine/extend shifts/move a buffer, what happens to throughput, WIP, and lead time?

- Start with what you have: connect Excel/CSV first, then scale to ERP/MES when ready.

Features That Fit SMEs

- Bottleneck Analyzer: spot bottlenecks immediately (example case: up to +10.5% output).

- Cost Analyzer & Energy Analyzer: analyze costs and usage patterns to reduce expenses in a structured way (example case: >20% reduction).

- Sankey Diagram: visualize in-plant movement and cut internal transport distance (up to 30%).

- Genetic Algorithm & Layout Optimizer: try alternative machine/aisle/storage positions to find the best solution (example case: 70% reduction in transport rate).

- Experiment Manager + What-if: test multiple scenarios quickly.

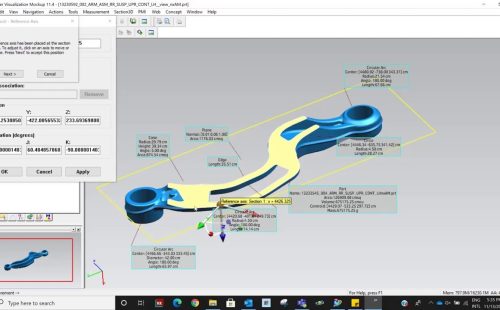

- Gantt & 3D VR Presentation: communicate results to executives with realistic visuals.

Note: The performance figures above are examples from real projects. Actual results depend on data quality and each factory’s scope.

SME-Friendly Way to Start — Fast Results, No Line Stops

- Discovery (free): collect pain points and basic data (throughput, cycle/idle time, line layout).

- Pilot Mini-Model: build a simple model from existing data (e.g., Excel) to find bottlenecks and test what-if.

- Quick Wins: pick the highest-ROI actions (layout/queueing/staffing/run schedules) and plan the roll-out.

- Scale up when ready: connect ERP/MES/IoT and set up dashboards for supervisors and executives.

Summary for SME Factory Leaders

Stop trial-and-error on the productionreal line. Perform the proper trials in a production simulation software that allows you to see results before investing. Make decisions with data—not gut feeling—and jump toward a Smart Factory today : start small, get real results.

Try First, Decide Later

Book a demo with our specialists and get the SME Starter Checklist free.

(30-minute online session)