Introduction

CO₂ reduction is a key priority across industries, reshaping production planning and operational efficiency.

Welcome to the forefront of innovation in manufacturing. At BSH Home Appliances Group, sustainability is embedded in every process. In this blog post was explore the latest initiatives to reduce CO2 emissions in the enameling process, an essential stage in home appliance production.

The Enameling Process

The enameling process plays a pivotal role in manufacturing, particularly in applying durable, protective coatings to metal components. Enamel coatings enhance surface resilience, aesthetics, and longevity.

This process involves multiple stages, including surface preparation, enamel application through spraying or dipping, and high-temperature curing in specialized furnaces.

CO2 Reduction in Enameling

Reducing CO2 emissions in enameling is a key focus for BSH Home Appliances. Efforts include optimizing furnace energy consumption, enhancing conveyor system efficiency, and implementing batch production strategies to lower overall energy demand.

Digital Transformation for Sustainability

The enameling process is a cornerstone of sustainable manufacturing. By refining production methods, manufacturers can align with environmental goals while maintaining operational efficiency.

Efficiency and Collaboration

Optimizing production requires a strategic combination of efficiency and collaboration. Integrated simulation tools enable precise factory planning, supporting continuous improvements in CO2 reduction. This approach is reinforced by knowledge-sharing, best practices, and extensive training programs.

Optimized Planning with Digital Tools

Easy Plan:

- Data Preparation

- Creation of Bill of Equipment (BOE)

- Equipment Configuration

- Definition of Plant Simulation Classes

- Bill of Process (BOP) Creation

- Production Line Setup

Teamcenter Integration:

- Definition of Plant Simulation Classes

- Equipment Configuration

- Attachment of MTTR (Mean Time to Repair) and Availability Data

- Product Assignment to Balancing Elements

A Holistic Approach to CO2 Reduction

Enameling presents an opportunity for substantial CO2 reduction. By optimizing coating application, merging flat parts and cavities in a single furnace, and redesigning conveyor systems, sustainability efforts drive both productivity and environmental responsibility.

Project Goals and Achievements

Key objectives included:

- Maximizing production capacity

- Enhancing conveyor efficiency

- Implementing batch processing strategies

Results:

- 50% reduction in CO2 emissions

- Fewer hangers required

- Optimized conveyor and workforce synchronization

Through meticulous planning and execution, BSH successfully maintained peak production efficiency while reducing environmental impact.

Engineering Sustainable Solutions: The Role of Simulation

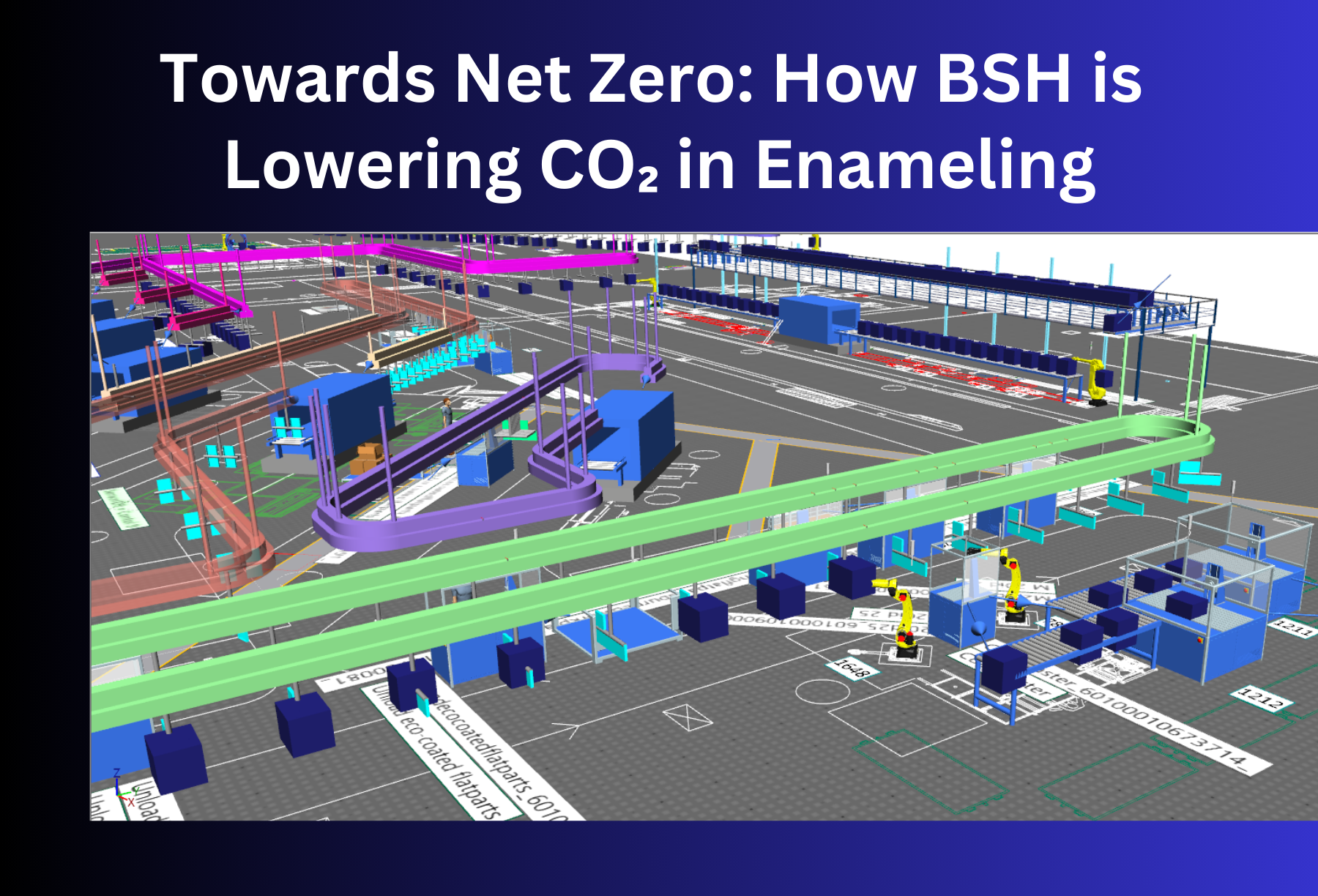

Every successful sustainability initiative is built on data-driven simulation and planning. The project incorporated:

- Advanced data analysis

- Equipment and process optimization

- Line balancing strategies

- 3D layout simulations

Leveraging tools like Easy Plan and AutoCAD ensured seamless integration of sustainable practices.

The Impact of CO2 Reduction

Beyond environmental benefits, reducing CO2 emissions drives operational efficiency, lowers resource consumption, and delivers cost savings. Sustainability initiatives also enhance corporate reputation, strengthening stakeholder trust and positioning BSH as a leader in green manufacturing.

Looking Ahead: Engaging in Sustainability

As manufacturing continues evolving toward sustainability, open discussions and innovative ideas are essential. Transparency, collaboration, and digital transformation will shape the future of responsible production.

Conclusion: A Shared Commitment to a Greener Future

Sustainability remains a core value at BSH Home Appliances. CO2 reduction in enameling is a testament to the company’s commitment to environmental responsibility and manufacturing excellence. By continuously pushing boundaries and embracing digital solutions, BSH invites industry professionals to join in the journey toward a cleaner, more sustainable future.