When the award-winning animation returns in a live-action adaptation, fans around the world are eagerly anticipating the reappearance of Toothless — the Night Fury dragon who captured hearts with his intelligence, loyalty, and irresistibly adorable look.

For engineering enthusiasts, one particularly thought-provoking moment comes early in the story: the scene where Toothless is unable to fly. Beneath the charming visuals lies a surprising amount of real-world aeronautical engineering principles.

In this article, I’ll guide you through a deep dive into the reasons why Toothless can’t fly on his own — from an engineer’s perspective. By drawing comparisons with airplanes, we’ll explore these concepts in a fun and easy-to-understand way.

Why Can’t Toothless Fly on His Own?

When we compare an aircraft flying in the sky to a creature like Toothless from How to Train Your Dragon, there are a number of engineering principles we can use to understand flight. For any aircraft, wings are essential for generating lift, allowing it to stay airborne. Additionally, thrust must be sufficient to overcome aerodynamic drag so the aircraft can reach a speed that produces enough lift to maintain flight, there are several other critical factors that aircraft designers must consider to ensure safe and optimal performance.

One of those key factors is predictable control and response—the aircraft must be able to respond reliably to either external forces or pilot inputs. For this to happen, the aircraft needs to possess what engineers call “aircraft stability.” Stability ensures that the aircraft maintains or returns to its intended flight path without erratic behavior, which is vital for safe and effective flight.

The fact that Toothless lacks a tail fin (or stabilizing rudder) could be one of the key reasons behind his inability to fly properly—it likely results in a lack of flight stability.

Flight stability comes from a balance of moments created by lift forces acting on different aerodynamic surfaces. Imagine Toothless gliding through the air: his wings generate lift, but so does the tail. The lift produced by both surfaces contributes to maintaining a stable flight.

To put it simply: when Toothless tries to pitch upward to gain altitude, the tail’s lift would typically act to bring him back into a balanced orientation. Similarly, in situations where there’s a crosswind, many might assume that Toothless would simply slip with the wind. However, if he had proper flight stability, the tail fin would help reorient him into the wind—allowing him to glide smoothly and regain control.

Without this stabilizing surface, controlling direction and maintaining balance in flight becomes significantly harder—just like a plane trying to fly without its tail.

Aircraft Stability

Aircraft stability refers to how an aircraft responds to disturbances from external factors—whether from natural forces like wind or from pilot input. It describes the tendency of the aircraft to return to its original flight condition or to continue in a steady path after being disrupted.

Generally, aircraft stability is categorized into two main types:

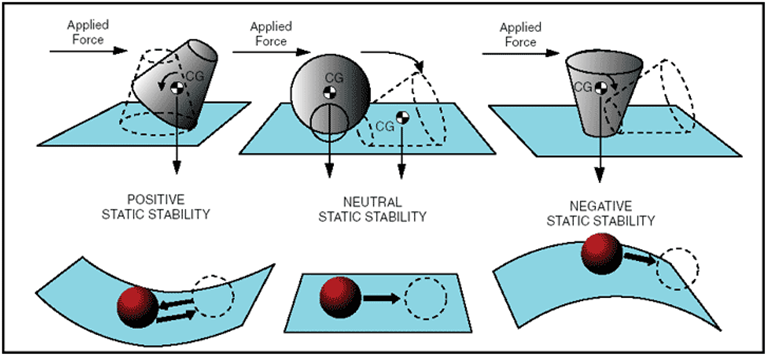

Static Stability

Static stability refers to an aircraft’s immediate, short-term response after being disturbed from its flight path. When a disturbance occurs—such as a gust of wind or an abrupt control input—the aircraft can exhibit one of three behaviors:

- Positive Static Stability The aircraft resists the disturbance and naturally tries to return to its original position or attitude. This is the most desirable trait for maintaining control and safe flight.

- Neutral Static Stability The aircraft does not attempt to return to its original state, but it also doesn’t diverge further. It simply remains in the new orientation or position without further reaction.

- Negative Static Stability The aircraft continues to move further away from its original position, becoming increasingly unstable. This is an undesirable condition that can make the aircraft difficult or impossible to control safely.

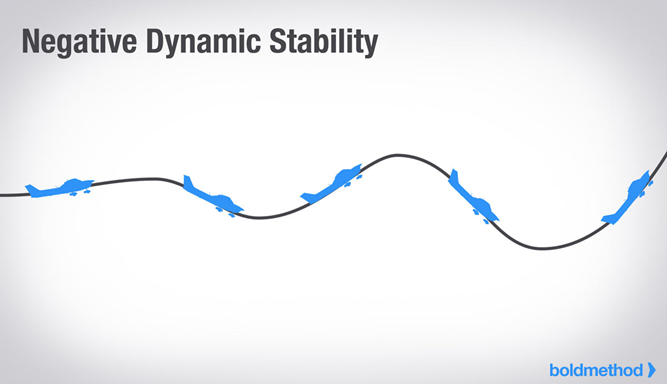

Some aircraft may exhibit good static stability—meaning they initially try to return to their original attitude after being disturbed. However, over time, their behavior might change and become increasingly unstable.

In such cases, even though the aircraft starts off with a tendency to recover, it gradually diverges from stable flight instead of settling down.

This condition is known as dynamic instability or dynamic unstable behavior.

Dynamic Stability

Dynamic stability refers to how an aircraft behaves over time after a disturbance has occurred and the disturbing force is no longer acting on it.

To put it simply: if an aircraft has positive static stability, it will initially attempt to return to its original flight attitude after being disturbed. However, this initial response doesn’t guarantee that the aircraft will actually return to a stable state—it only indicates a tendency to do so.

Dynamic stability measures whether the aircraft truly returns to equilibrium over time, and how long it takes to do so. An aircraft with good dynamic stability will gradually settle back into smooth, level flight. But if it oscillates more and more or fails to stabilize, it’s considered dynamically unstable.

So, while static stability is about the direction of the response, dynamic stability is about the outcome and behavior over time.

Toothless’s missing tail is similar to an aircraft’s vertical and horizontal stabilizers, which play a crucial role in balancing the moments around the pitch and yaw axes.

This explains why Hiccup’s design of the prosthetic tail helped Toothless fly again. Although it took some time to adjust the tail surface area to generate the right amount of lift and restore the balance of moments, the artificial stabilizer eventually allowed Toothless to regain stable flight.

Potential Future Problems?

Although Hiccup successfully crafted a prosthetic tail to help Toothless regain flight stability, if the effects of aeroelasticity are not properly considered, Toothless may face issues that prevent him from flying as steadily as before.

What is Aeroelasticity?

Aeroelasticity is the study of the interaction between aerodynamic forces and the elastic forces of structures—such as airplane wings or, in this case, Toothless’s prosthetic tail fin.

When a flexible object is exposed to airflow, it often bends or twists. This deformation affects the direction of the airflow, creating a feedback loop of interacting forces.

If this interaction is not properly controlled, it can lead to severe vibrations known as flutter, which may cause structural instability or even damage to the wing or tail.

Flutter

Flutter is a key phenomenon in aeroelasticity, caused by the continuous interaction between inertial forces, elastic forces, and aerodynamic forces. This interaction leads to increasing vibrations that can eventually result in severe structural damage.

Flutter isn’t a concern only for aircraft. It can also occur in other structures—especially in environments with strong winds and consistent vibrations. Examples include light poles, traffic signs, bridges, and tall buildings.

Challenges in Aerostructure Analysis

In the world of aircraft structural design and analysis, the process is often fragmented. Typically, CAD software—most commonly CATIA—is used separately from FEM analysis tools, and critical calculations such as Margin of Safety are often done manually in Excel, disconnected from any integrated system.

This lack of connectivity introduces several risks and inefficiencies, such as:

- Data translation errors between software platforms

- Redundant work due to an inefficient workflow

- Difficulty in implementing design changes, as updates must be made manually across multiple tools

- Delays in analysis and certification processes, which are critical for regulatory approval

This fragmented approach can significantly hinder both productivity and accuracy in aerospace engineering projects.

To address these challenges, Siemens has developed Simcenter 3D Aerostructure—an end-to-end platform for aircraft structural engineering. This solution integrates the entire process into a unified environment, covering every critical step, including:

- Importing CAD data

- Creating and refining FEM models

- Flutter analysis

- Calculating the Margin of Safety using international standards or organization-specific methods

- Generating certification-ready reports directly within the software

By streamlining workflows and reducing data transfer errors, Simcenter 3D Aerostructure helps accelerate development, improve accuracy, and support faster certification.

By working within a single integrated platform, users can reduce development and structural analysis time by up to 30%. Additionally, geometry modifications become significantly more efficient thanks to the direct connection between CAD and CAE, enabling seamless updates and faster iteration throughout the design process.

Conclusion

The story of Toothless is more than just a heartwarming animated film—it also offers a fascinating reflection of real-world aeronautical engineering principles, from flight stability to structural behavior under aerodynamic loads.

In the real world, engineers can’t rely on basic understanding alone. They need powerful tools that ensure aircraft structures are designed, analyzed, and certified with efficiency, safety, and precision.

Simcenter 3D Aerostructure by Siemens is that solution.

It’s a comprehensive, all-in-one platform that seamlessly connects design, analysis, and certification processes in a single environment.

If Hiccup had access to Simcenter 3D Aerostructure from the start, he might have helped Toothless fly again—faster, safer, and ready to take on any aerial mission.

👨🏻💻 Written and Analyzed by:

Nithikit Thanateerarangsan

Manufacturing Dept. Team Leader

Expert and certified CAE solution trainer with experience in UAV aerodynamic simulation (CFD), portable credit card mechanism analysis, heat-related failure analysis of outdoor AC units, pressure loss analysis in air ducts, and more.

Connect Author’s LinkedIn : www.linkedin.com/in/nithikitt